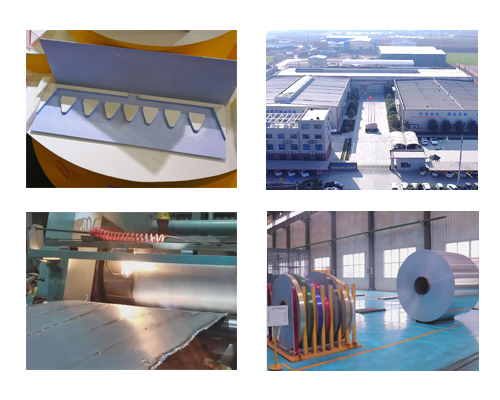

AdTech Aluminum Silicate Casting Nozzle Plate is used for the crystal forming and size control of aluminum plates and foil blanks in the casting and rolling production line. It is made of nano-fiber composite materials processed by vacuum filtration and high-precision equipment. AdTech high-silicon casting nozzle has uniform short fiber structure distribution, moderate density, good heat preservation, accurate size, high oxidation resistance, no delamination, no deformation, small deformation, and effectively protect the surface of the cast-rolled coil. The quality of the boron nitride coating is better.

Aluminum silicate casting nozzle is a key component of aluminum strip continuous casting and rolling mill. The quality of castings directly affects the quality of strip steel and the yield of production. Aluminum silicate casting nozzles can be divided into various models according to the performance and needs of different casting machines.

In the aluminum alloy casting and rolling process, the gate made of refractory materials is indispensable. The adjustment of the gate opening and the adjustment of the plate shape are important reuse in the production of aluminum products. Therefore, it has a great impact on product quality. Big. In the related art, the pouring nozzle includes an upper clamping plate located at the upper part of the pouring nozzle and a lower clamping plate located at the lower part of the pouring nozzle, and the upper clamping plate is clamped with the lower clamping plate.

The aluminum silicate casting tip and nozzle produced by AdTech is made of high silicon and other materials. It has the advantages of good elasticity, no deformation, and long service life. The special process can effectively prevent the molten aluminum from corroding the casting nozzle and avoid carbonization; the fracture structure is a fine and uniform layered fiber structure to prevent the existence of flocculent structures; the working surface coating is uniform and smooth to prevent particle cracks and coating shedding, provide a guarantee for high-quality cast-in-place slabs.

Pingback:MALAYSIAN ALUMINIUM & ALLOYS SDN BHD-Adtech