Casting and rolling process of aluminum strip is to use aluminum as the main raw material and melt it with other alloy elements, and then die-cast it.

After the materials are melted at high temperature, they are directly cast into products. Generally, it is melted in an electric arc furnace, then poured into a high-temperature resistant mold, and then cooled, crystallized, annealed or cut into products. In production, the melting atmosphere, melting temperature and cooling conditions are controlled to ensure high production efficiency, crystallization meets the requirements and formation of a network structure.

Several key parameters in the casting process:

1. The furnace temperature is generally set at 1050°C during smelting, and the material temperature needs to be monitored during the process to control the metal temperature to not exceed 770°C.

2. Carry out slag-skimming operation at around 735°C, which is favorable for slag-liquid separation.

3. Refining generally adopts secondary refining method, primary refining with refining agent, and secondary refining adopts gas refining method.

4. Generally 30min-1h after inverted furnace should be cast in time, otherwise it needs to be refined again.

5. Ai-Ti-B wire needs to be continuously added during the casting process to refine the grains.

6. Degassing and filtering process is important for obtaining the clean liquid metal.

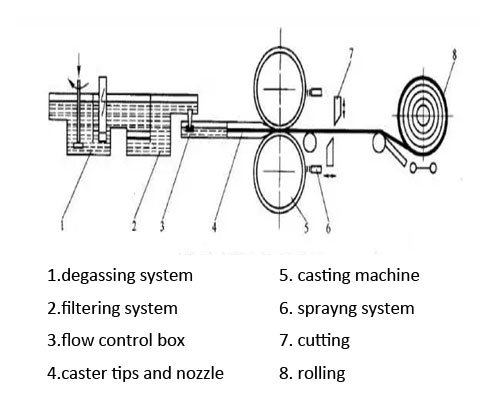

Casting and rolling process: liquid metal, flow control box (liquid level control), casting and rolling mill (lubrication system, cooling water), shearing machine, coiling machine.

The casting-rolling temperature is generally between 680℃-700℃, the lower the better, the stable casting-rolling line usually stops once more than a month, and the plate is re-upped. During the production process, the front box liquid level must be strictly controlled to prevent the liquid level. low.

The production speed is generally between 1.5m/min-2.5m/min. The surface quality of cast-rolling products is generally low, and generally cannot meet the requirements of products with special physical and chemical properties.