In aluminum casting production, the casting rejection rate due to casting defects such as non-metallic inclusions generally reaches 50% 60% of the total number of rejects. Inclusion defects not only severely reduce the mechanical properties of castings, but also have a harmful effect on their processing properties and appearance. Purifying liquid casting alloys and reducing or eliminating various non-metallic inclusions is undoubtedly a very important technical measure to obtain high-quality castings. Since the first successful research of ceramic foam filter for aluminum alloy in 1978, ceramic foam filter technology has developed rapidly. The use of ceramic foam filter technology can effectively achieve the purpose of purifying molten aluminum alloy.

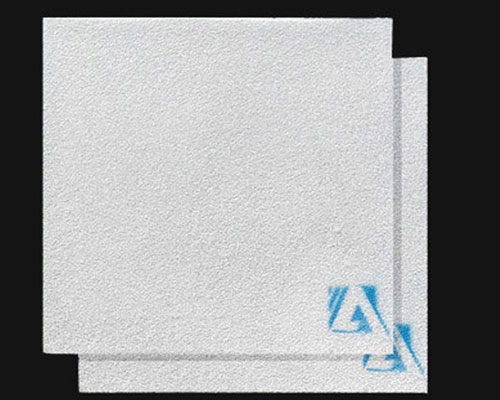

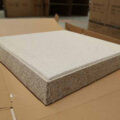

The ceramic foam filter (CFF) for aluminum alloy uses polyurethane foam as a carrier and immerses it in a coating made of ceramic powder, binder, sintering aid, suspending agent, etc., and then squeezes out the excess coating. The ceramic coating is evenly coated on the carrier frame to form a green body, and then the green body is dried and baked at high temperatures.

Foam ceramic filters are divided into bonding type and sintering type. The former relies on a binder to bond the ceramic fine particles together, and the latter relies on heat preservation at high temperature to sinter and fuse the purer ceramic fine particles.

The unique three-dimensional connected curved-hole mesh skeleton structure of the ceramic foam filter makes it have an open porosity as high as 80%-90%, and has the following three filtration and purification mechanisms:

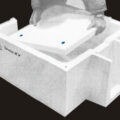

One is mechanical interception. The second is the rectification scum, that is, the rectification effect of the filter makes the runner in front of the filter full, so that the filtered aluminum water is in a smooth laminar flow state, and the oxidation and erosion reaction of the aluminum water is weakened, thereby causing inclusions are easy to float and capture, so that the number of secondary inclusions after the filter is reduced. The third is deep adsorption, that is, the small inclusions that enter the filter are adsorbed on the skeleton or trapped in the dead corner of the network due to full contact with the ceramic network with complex flow path.

The ceramic foam filter for aluminum alloy adopts these three filtering and purification mechanisms to efficiently filter out large inclusions and some small suspended inclusions as small as tens of microns in the molten metal.