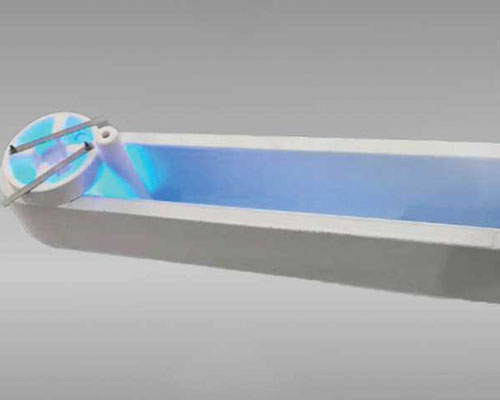

AdTech ceramic launder uses a new high-silicon molten material molding technology. It has a dual function: conveying and heat preservation. Molten aluminum launder liner can be used multiple times. AdTech casting launder has a certain corrosion resistance, non-stick aluminum, no pollution to aluminum liquid performance. Refractory launder is mainly suitable for aluminum alloy products, such as aviation, transportation and other precision castings, and rolling medium-micron aluminum foil.

Specification

| Item | Length | Flow Control Complement | Special Specifications |

| Standard | 200-3000mm | According to the drawings | According to the drawings |

Technical parameters

| Item | Density g. cm3 |

Rupture modulus (816℃ Mpa) |

Thermal expansivity (680℃ K-1) |

Thermal conductivity540℃W/k.m | Max operating temperature (℃ ) |

| Index | 1.0-1.4 | 10.5-11.8 | 1.23*10-6 | 0.5-0.65 | 1260 |

Ceramic Launder Advantages

- Good thermal insulation performance, low density, good non-stick aluminum performance, and good operability in casting and rolling.

- Adopts high-silicon molten material, has high dimensional accuracy.

- Can be used repeatedly or multiple times, the surface is smooth.

Refractory Troughs are one of AdTech Refractories primary product offerings. There are a number of shapes and sizes. Our high-quality launders have been provided to both aluminum industry customers and non-ferrous market. We have experience in producing a large variety of different shapes for our customers in different industries. We can often provide insight into the causes of premature launder failures and offer material or design change recommendations to correct the problems. We have provided customers with refractory launder lines, as well as designed and built entirely new custom launder systems.

Instructions

- Corresponding to the drawing structure, install the movable ceramic launder. Ensure that the movable launder is clean, free of damage and seamless.

- Warm up the installed movable groove evenly, and heat up at a uniform speed for 1-2 hours. So as to remove the adsorbed crystal water, close to the casting temperature.

- The movable runner has no electric heating and baking conditions, so it has to be baked by flame. The first key is to control the flame temperature. The second is to prevent the flame from roasting directly, otherwise, the local heating can easily cause the liner to burst. The flame is divided into weak flame (red soft flame), medium flame (yellow), and strong flame (blue and white).