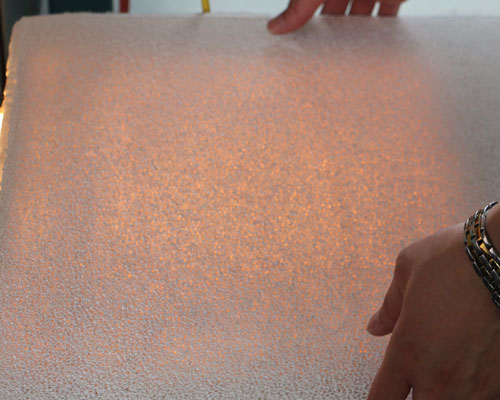

Ceramic foam filter uses a perfect three-dimensional structure, it has an excellent filtration effect on aluminum water, can effectively remove oxide inclusions and other non-metallic inclusions by blocking adsorption. After the ceramic foam filter filtration, the product quality will be very stable, satisfactory results.

Ceramic foam filter screen has the characteristics of large specific surface area, high mechanical strength, and heat shock resistance.

Purification of metal liquid, removal of non-metallic impurities and gases.

The filling of liquid metal is stable and the vortex is reduced.

Simplify the gating system and improve the process yield.

The porosity of casting can be reduced and the metal structure can be optimized and refined.

It can improve the surface quality and mechanical properties of castings and reduce the reject rate of castings.

It can reduce machining allowance, increase tool life and reduce casting cost.

Foam Ceramic Filter Uses

In general, the following aspects should be paid attention to in the installation and use of alumina ceramic foam filter plates:

Correct selection of filter plate: in the selection of filter plate size and specification of hole number, it is necessary to consider the factors of pouring flow range, specific type of metal filtration, maximum level, the total amount of filtration, and original aluminum liquid cleanliness.

The pretreatment of melt filtration can not be ignored, such as normal slag removal of furnace and holding furnace, cleaning furnace, refining, etc. In particular, the on-line degassing device is still necessary because it can not only reduce the hydrogen content in the melt, but also remove some non-metallic inclusions

The filter should be matched with the square high temperature filter box: not only for sealing, but also to prevent metal from filtering, from the notch into the box, and avoiding the too light foam filter plate, and the aluminum water fails.

Preheat before use: preheat to remove moisture and facilitate initial instantaneous filtration. Preheating can be achieved by electric or gas heating. Normally, about 15 minutes.

Normal filtration process, without slag, avoid knocking, vibration filter plate. At the same time, water should be sufficient to avoid too much movement of aluminum and water in the tank.

After casting, dry the metal for cleaning and ceramic filter plate. As a vibrator, the filter plates are mounted on one-minute vibration, from the retention of 75% liquid filters on the metal liquid.

Finally, the ceramic filter plate is cleaned around, and then the filter plate is removed by coagulation.