Aluminum alloy melting is the first process of aluminum alloy processing, and it is also a crucial link. The technology of alloying, purifying and refining is embodied in the melting process. Removal of non-metallic inclusions in aluminum alloy melts, treatment of flux in furnace and Foam Ceramic Filter outside the furnace have become an important means of purifying aluminum melt.

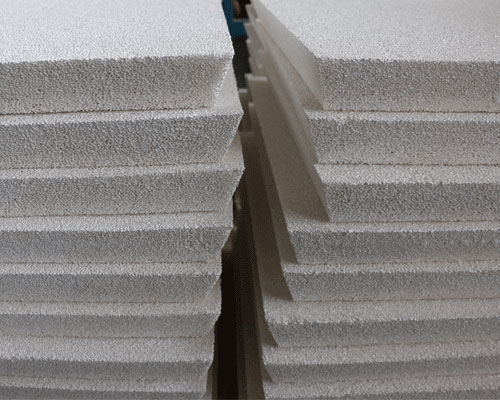

Foam Ceramic Filters are a porous ceramic product with a porosity of up to 80-90% and a volume density of only 0.3-0.6g/cm3, which has a unique three-dimensional network skeleton and pore structure. The removal of impurities by ceramic filter can significantly improve the quality of ingot and reduce the reject rate. Ceramic foam filter materials have been developed and developed around the world, promoting the widespread application in the metallurgical industry.

The production of ceramic foam filters is generally based on a three-dimensional network structure and an organic foam plastic with connected pores as a carrier. It is immersed in a special ceramic slurry with thixotropy, and a special roll extrusion process is applied to make the ceramic slurry uniformly applied to the skeleton of the carrier, but then dried and solidified and then roasted at high temperature.

Ceramic Filter Application

Ceramic foam filter for casting application has two modes:

One is the semi-continuous casting of flux in the furnace and the ceramic foam filter outside the furnace. The ceramic filter plate is replaced by new for each casting. Today, some aluminum factories add slot type online degassing machine before filtration, improve the purification effect.

The second is the continuous casting and rolling line, and the replacement is based on the pressure difference before and after the filter plate to determine the replacement cycle. As for the selection of the large size, it is determined according to the unit time, flow volume and total volume of the aluminum liquid. And the ceramic filter board with large number of mesh holes is determined by the cleanliness requirement of the final molten aluminum. The higher the cleanliness requirement of the aluminum liquid is, the smaller the pore size of the choice is, and thus new requirements for the structure and material quality of the foam ceramic filter are put forward. With the development and application of various purification technologies of aluminum, foam ceramic filtration and purification are the last process of aluminum liquid purification. Before this procedure, flux refining or on-line rotary degassing technology has been used.