Hot-top casting parts include Distribution Plate, Thimble, Transition Plate, Graphite Ring, Flow Control Box, Removable Launder, etc. Hot-top casting is appropriate for casting connect between distribution plate and aluminum billet casting.

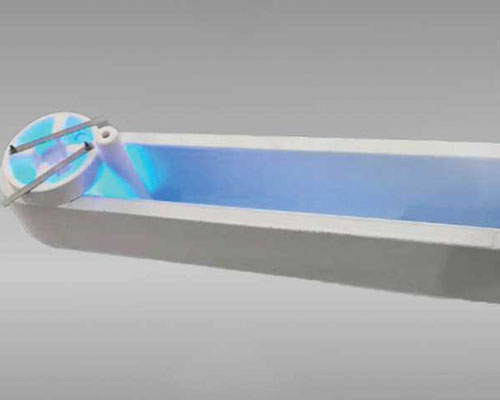

Distributing Launder

AdTech Distributing Launder adopts two kinds of materials: high silica 140 materials and Al-Si materials. Casting thimble, distribution plate, transition plate, hat plate, graphite ring, distribution launder, and other products. They are always used cooperatively for precision casting, especially matching with Wagstaff. Pour the molten aluminum into the mold crystallizer and form the final product. It is an important part of the hot top casting. It can meet the technical requirements with high value-added, high technical performance, such as aviation, transportation, electronic products, and other aluminum alloy precision casting.

Learn MoreCeramic Sprue Bush

AdTech Ceramic Sprue Bush adopts two kinds of materials: high fused silica materials and Al-Si materials. It is a key part of hot-top casting. AdTech thimble has high corrosion resistance, high geometry precision, smooth surface, long service life, low maintenance cost, and non-pollution to molten aluminum, especially suitable for Wagstaff equipment. The molten aluminum is poured into the mold crystallizer from the distribution plate during casting. It can meet the technical requirements of precision casting of aluminum alloy.

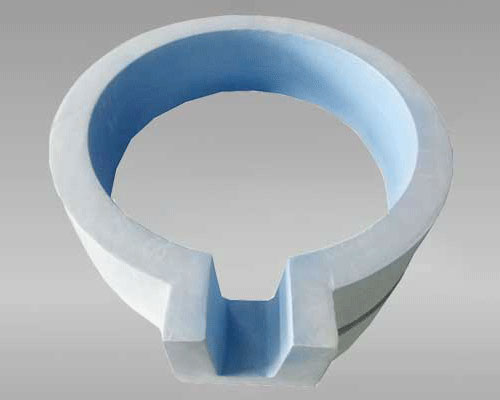

Learn MoreAlumina Ceramic Ring

AdTech Alumina Ceramic Ring adopts three kinds of materials: N17, Sigma and Al-Si materials. It is always cooperatively with the thimble, distribution plate, hat plate, graphite ring, distribution launder and other products installed in casting equipment, especially match with Wagstaff equipment. It is the best choice for hot-top casting with high corrosion resistance, high geometric precision, smooth surface, long service life, low maintenance cost and non-pollution of molten aluminum. The molten aluminum is poured into the mold crystallizer from the distribution plate during casting. It can meet the technical requirements of precision casting of aluminum alloy.

Learn MoreGraphite Ring

High purity graphite ring uses high purity graphite material, and used for precision hot-top casting for aluminum alloy, match with casting machine to control the dimension and smoothness.

Learn MoreFlow Control Box

The flow control box replaces the traditional manual work. It can be used repeatedly and reduce 3-4 times cost compared with traditional materials. The flow control box has the function of automatic flow control and reduces labor costs and improves the stability of the metal flow. AdTech flow box uses high silicon molten material molding technology. It has certain corrosion resistance, non-stick and non-pollution molten aluminum. It can effectively protect the stability of the internal organization layer of the cast and rolled foil.

Learn MoreHot Top Casting Cap

AdTech hot top casting cap uses high silicon melting 140 materials. It is the best choice for hot-top aluminum casting. It has high corrosion resistance, high geometric precision, smooth surface, long service life, low maintenance cost and non-pollution to molten aluminum. AdTech hot top casting cap can meet the high value-added, high-tech performance aluminum casting requirement.

Learn MoreCeramic Launder

AdTech Ceramic Launder has dual functions: transport and insulation. Removable launder uses high fused silica material, has a reusable or multiple-use liner. Its density is 1.0-1.4g/cm³.

Learn More