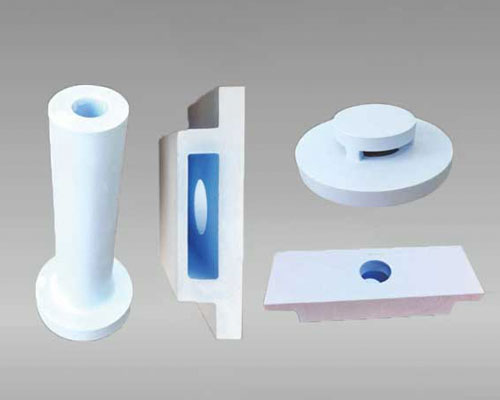

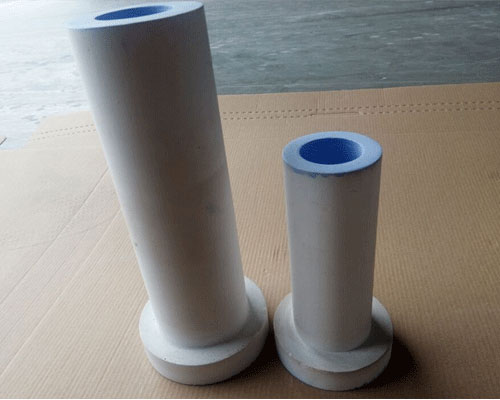

Ladle shroud and float plate adopt SiO2 materials. They can adjust the flow of molten aluminum in the metal casting industry. The flow tubes and float plates have the advantages of light weight, high-temperature resistance, small thermal conductivity, and good thermal insulation performance. They are refractory and heat insulation materials, widely used in melting furnaces, and various industrial furnaces. AdTech company can also provide customers with a variety of products, such as silica-alumina fiber paper, plugs, thermal caps, ceramic foam filters and so on.

Ladle Shroud Specification

| items | Dimensions | Special dimensions | Package | Special package |

| Flow pipe | 100-650mm | As drawing | 50pieces/box | As required |

Ladle Shroud Advantages

- Use with the boron nitride (BN) paint, the life can increase 50-100 times.

- High wear resistance: the rub proofness is 4-7 times than of steel pipes, and 4 times than nylon.

- High corrosion resistance: UHMWPE has a saturated molecular structure, extremely high chemical stability, and is resistant to various corrosive media and organic solvents.

- High flexibility: elongation at break can reach more than 400%.

- High impact resistance: The impact strength ranks first among various plastics, 10 times than high-density polyethylene.

- Low-temperature resistance: Excellent low-temperature resistance, the impact strength reaches the highest value at minus 40 ° C.

- Smooth structure: the inner and outer walls of the pipeline are smooth, has excellent non-stick and self-lubricating properties.

- Anti-aging properties: anti-aging properties are better than PE100.

- Safety and environmental protection: non-toxic and tasteless.

- Convenient installation: the pipe connection is directly flanged by the pipe body, and no seal.

Instructions

- Corresponding to the drawing, install the flow tube and float. Ensure the smooth and clean, no damage.

- Check whether the sealing around the flow tube and floating installation is intact. It is best to use seal materials, such as ceramic fiber paper, ceramic fiber blanket.

- Regulate the controller system of the flow controller, so as to achieve precise assembly and use.

The flow direction of molten aluminum is from right to left, and the flow of molten aluminum during normal casting and rolling is controlled by the gap between the plug and the flow control tube. The installation horizontal position of the float is at the level of the front box during normal rolling. During the initial rolling, the height of the float can be adjusted by adjusting the adjusting nut. The height of the aluminum liquid on the right side of the flow control baffle is higher than the flow control flow on the left. The aluminum liquid level inside the tank.

The float plate is located on the surface of the molten aluminum, and its height is adjustable. It is used to adjust the height of the molten aluminum in the front box and fluctuates with the height of the molten aluminum in the flow control trough to provide power for the entire flow control linkage. When the molten aluminum in the flow control trough is lower than the set height, the float drops. Because the float is linked to the plug, the float drives the plug away from the flow control port.

Increase the outflow of molten aluminum, and the liquid level in the flow control trough gradually rises, slowly pushing the float upward. When the molten aluminum in the flow control trough is higher than the set height, the float rises, driving the plug to move toward the flow control port, reducing the flow of the molten aluminum out, and the liquid level in the flow control trough gradually decreases, and the float will slowly Move Downward. When the actual height of the liquid level reaches the set liquid level, the entire coupling is in a dynamic balance and no longer has too much action. Therefore, when the liquid level needs to be raised or lowered in actual production, only the height of the float needs to be adjusted. That’s it, the operation is convenient and simple.