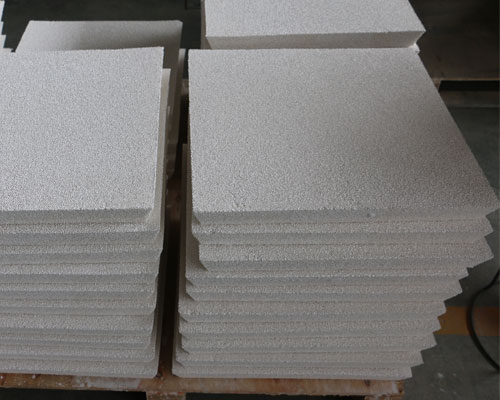

Aluminum Foundry Filter is produced based on a solid network structure carrier and a combination of organic foam pores. It is used for the filtration of molten aluminum in the production process of aluminum rod factory.

The production process is as follows. The alumina carrier is put into the thixotropic slurry, and the automatic extrusion process is corrected by the square center, so the foamed slurry is evenly deposited on the bone carrier. After drying and solidification, the carrier will be converted into the final product baked at a high temperature of 1180°C Formed under.

The Aluminum Foundry Filter is installed in the filter cartridge to filter the impurities in the molten aluminum alloy to meet the needs of the production of aluminum alloy precision castings with high added value and high technical performance, such as computer hard disks, PS substrates for printing, canned materials, and turbojet engines Fan blades, etc.

The ceramic foam filter is surrounded by a sealing gasket, which is placed between Ceramic Foam Filtering System and the filter bowl to prevent the molten aluminum from leaking from the interface. AdTech foam ceramic filter uses three different types of sealing gaskets: fiber paper material, fiber cotton material, and expanded cotton material.

Aluminum Foundry Filter must be based on the flow of molten aluminum. Secondly, consider the cleanliness of the melt, the maximum inclusion content, and the total output of the melt.

The filtering effect of the molten metal filter is mainly ensured by its size and porosity. The greater the porosity of the filter plate, the worse the slag removal effect. For aluminum castings with higher requirements, foam ceramic filters for casting with smaller porosity should be used.

Ceramic Foam Foundry Filter is mainly used in aluminum rods, aluminum ingot, aluminum plate foundry workshop. Due to its excellent resistance to corrosion and corrosion of molten aluminum, it can effectively remove inclusions, reduce trapped gas, provide laminar flow, and significantly clean the filtered metal. Cleaner metals can lead to higher-quality castings, less scrap, and fewer inclusions, all of which contribute to profits.