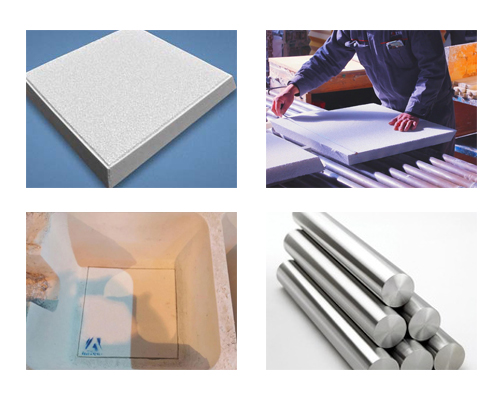

Aluminum ingot casting filter is also used for high-precision filtration and purification of aluminum smelting products such as aluminum rods and aluminum foil. The aluminum ingot ceramic casting filter is surrounded by a sealing gasket, which is used to seal in the filter box to prevent liquid aluminum from leaking from the contact surface.

The casting filter of aluminum ingot can effectively remove the large inclusions in liquid aluminum, absorb the micron particles of small inclusions, improve the surface quality of aluminum rod, aluminum ingot and aluminum foil, and improve the product performance. It is widely used in aluminum profile, aluminum foil, aluminum alloy, and other production fields.

In the production of aluminum ingots, foam ceramic filter metal liquid filtration technology is adopted. Through mechanical filtration, rectifying scum, and deep adsorption, three kinds of filtration and purification mechanisms can effectively reduce or eliminate the non-metallic inclusions and purify liquid alloys, thereby improving the production rate and qualified rate of aluminum ingots.

Because of the low melting temperature of aluminum alloy, the high temperature performance of foam ceramic filter material is not high, alumina foam ceramic filter can be used.

Alumina Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. Our alumina ceramic foam filter uses good portiforium foam and high purity ceramic as raw material, can remove non-metal solid mixture from molten aluminum and aluminum alloy effectively in your aluminum casting industry.

They are manufactured with porosities varying from 10 to 60 pores per inch (PPI). Also, combo sets are made in 20-30 PPI and other selections are possible. Different sizes and custom-made filters are manufactured according to specifications.

Aluminum Ingot Casting Filter Features:

- Machined to tight dimensional tolerances.

- Excellent strength and thermal properties.

- Resistant to molten aluminum attack.

- Available in various sizes and grades.

- Reduced scrap.

- Increased metal quality.