Alumina is the common name of aluminum oxide (Al2O3). Alumina is produced from bauxite, which is ore mined from topsoil in various tropical and subtropical regions. The Bayer method discovered in 1887 is the main method for extracting alumina from bauxite. In order to produce pure aluminum, it is necessary to use the Hall-Héroult electrolysis process to smelt alumina. This process is called primary production. AdTech offers degassing units, CFF filters, refining fluxes for Aluminum Oxide Refining.

Alumina is usually called aluminum oxide, which is a compound composed of aluminum and oxygen molecules (Al2O3). After refining from bauxite, alumina usually looks like a white powder, similar to table salt or granulated sugar. Alumina is usually called aluminum oxide, but it can also be called aloxide, aloxite or alundum, depending on the industry and the use of the metal.

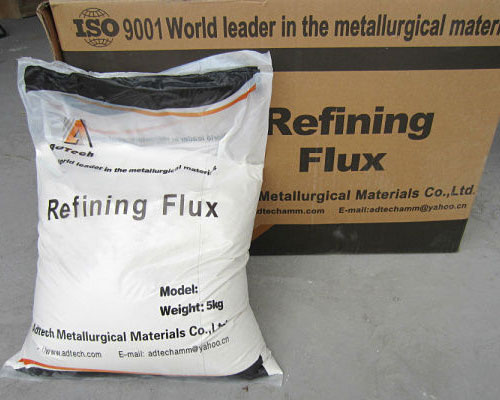

Aluminum Oxide Refining

In addition to the production of primary aluminum, alumina also has other key industrial uses. Alumina is commonly used as a filler in plastics. The compound is also widely used as an abrasive and is a cheap alternative to industrial diamonds. Alumina flakes have a reflective effect on automotive paints. The largest use of alumina occurs in refineries, where alumina compounds are used to convert dangerous hydrogen sulfide waste gas into elemental sulfur.

Alumina in its natural, free form is called corundum. In special cases, corundum will form sapphires and rubies. These gems can be produced synthetically, sometimes called alumina. The term is usually limited to synthetic gems used in the metallurgy, ceramics and chemical processing industries. Naturally formed rubies and sapphires are two of the four types of gemstones, and emeralds and diamonds are the other two.

Aluminum can be fused with special films to form flexible packaging. Increasingly, aluminum foil and flexible films are being fused together to make lightweight, flexible packages. This technology allows the packaging to expand to the shape of its contents and then shrink as the product is consumed.