When the thickness of the cast-rolled sheet is thicker, due to the certain temperature difference between the upper and lower surfaces of the melt in……

The filter box has a variety of styles, including single-chamber and double-chamber; filters include vertical single-plug, double-plug, multi-plug, horizontal type with heating and insulation, and……

Preparation before the casting process The working surface of the crystallizer is smooth, and the inner surface is polished with sandpaper when using ordinary molds.……

The slag mixed into the ingot or other non-metallic impurities falling into the ingot are called non-metallic inclusions. The fracture features are black strips or……

The cast-rolled strip contains slag, flux, various refractory fragments, metal oxides and other impurities, which are called inclusions. There are many kinds of inclusions in……

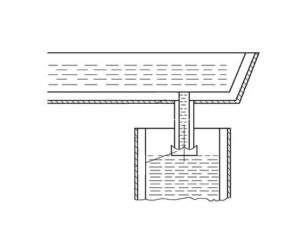

Ceramic filter device currently used in some factories. The outer shell of the filter is welded by steel plates, lined with aluminum silicate fiber felt,……

The important requirement of the ingot structure is that the inside is composed of fine and uniform spherical casting grains. For different alloy systems, the……

Under stable conditions, when the casting-rolling temperature is constant, the headbox temperature is also constant. Because the melt temperature in the front box is easy……

The main function of the casting system in the strip casting and rolling production line is to transport the liquid aluminum from the static furnace……

The main function of the pouring system is to transport the liquid metal from the static furnace to the feed nozzle. During the transportation process,……