The slagging and degassing methods in the smelting process of aluminum and aluminum alloys can generally be divided into flux covering and inert gas protection……

The covering agent can generate a molten layer to protect the metal from oxidation and hydrogen absorption. They gather oxides and non-metallic materials in the……

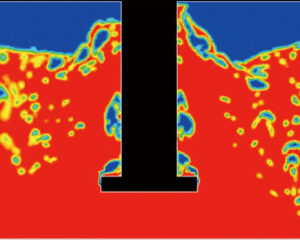

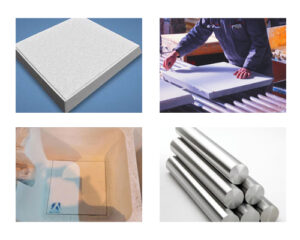

The plate filter equipment mainly filters the aluminum liquid through the ceramic foam filter. The foam ceramic filter plate is currently the most effective tool……

The hydrogen removal process is the gas purification process. Artificially add inert gases (Ar, N2, etc.) or active gases that are insoluble in the aluminum……

The comprehensive purification of refining agent and CFF filtration is the aluminum melt purification technology commonly used by the majority of aluminum processing enterprises. This……

The quality of molten aluminum flow control in the aluminum alloy casting process is a key factor in determining the quality of the ingot. Especially……

In order to further control the content and size of inclusions and eliminate the harmful effects of large-particle inclusions, most of the aluminum melt purification……

Casting is the pre-process of hot rolling, and the quality of the billet directly affects the quality of the final product. Most aluminum processing enterprises……

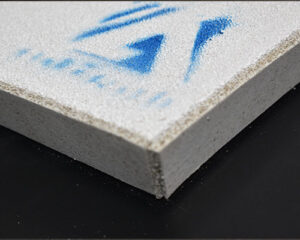

Foam ceramic filters for metal casting have been widely used in aluminum foundry because of their good economic benefits and strong impurity removal function. The……

The installation of ceramic foam filter depends on the type of sealing liner. When using the ceramic foam filter with expanded cotton edge sealing liner,……