The hydrogen removal process is the gas purification process. Artificially add inert gases (Ar, N2, etc.) or active gases that are insoluble in the aluminum melt (Cl2, C2Cl4, etc.) into the aluminum melt, so that the hydrogen melted in the aluminum melt is absorbed by these gas bubbles. The bubbles float upward and escape the aluminum melt.

The gas purification process can be divided into the following steps:

Through convection and diffusion, the hydrogen atoms in the aluminum melt migrate to the gas-liquid interface between the aluminum melt and the bubbles added.

The hydrogen atom changes from the dissolved state to the adsorbed state.

The adsorbed hydrogen atoms at the gas-liquid interface interact with each other to form hydrogen molecules.

Hydrogen molecules desorb from the gas-liquid interface.

The molecules diffuse into the gas phase and float up with the added gas bubbles to escape the molten aluminum.

The basic way to improve the gas purification effect is:

It is possible to increase the number of bubbles added to increase the effective contact area between the aluminum melt and the bubbles.

Reduce the diameter of the bubbles added as much as possible and increase the contact area between the gas and the aluminum melt.

Extend the floating distance of the added bubbles in the aluminum melt as much as possible, increase the residence time of the bubbles in the aluminum melt, that is, increase the time for aluminum melt gas purification process.

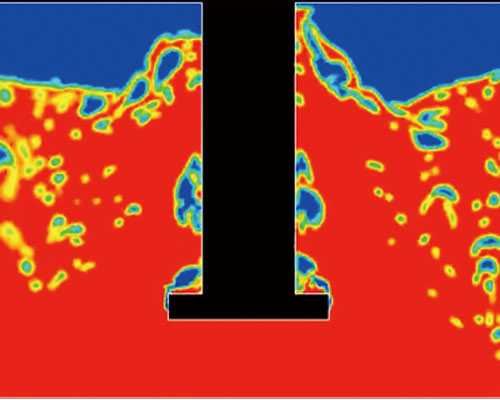

Around these three basic ways, there are more advanced MINT, SNIF, FILD, online degassing, and purification technology. The basic principle is to use the mechanical rotation of the blowing head and the blowing effect of argon or nitrogen to break the inert gas introduced into the molten aluminum into small groups of bubbles, which slowly rise from the molten aluminum, thereby significantly increasing the contact between the gas and the liquid area, prolong the action time, and improve the degassing efficiency. At the same time, due to the strong stirring of the blowing head, the small inclusions are gathered into larger agglomerates, and the dense small air group has a high probability of catching slag, thereby also improving the efficiency of slag removal.