The ceramic foam filter increases the flow resistance of the molten aluminum, prolongs the average residence time of the molten aluminum, and reduces the volume fraction of the dead zone of the tundish. Ceramic foam filters can significantly improve the removal rate of small-size inclusions, and can also offset part of the decrease in the removal rate of inclusions caused by increased density.

During the continuous casting production process, due to the desulfurization, deoxidation, alloying of molten aluminum, the interaction between molten aluminum and slag, and the melting loss and spalling of refractory materials such as furnace linings, various oxides, nitrides, and sulfides will be produced. Non-metallic inclusions. These non-metallic inclusions seriously affect the strength, toughness, and fatigue resistance of aluminum products, and reduce product reliability.

As the last place to remove inclusions before molten aluminum continuous casting, the tundish has an important impact on the cleanliness of molten aluminum. In order to improve the removal rate of inclusions, current control devices such as turbulence suppressors and weirs are generally installed in the tundish to improve the flow field and temperature distribution of the molten aluminum, thereby promoting the floating removal of inclusions. However, general flow control devices can only remove large-sized inclusions. For inclusions with a size less than 50 μm, the floating removal effect is not ideal due to the limited buoyancy.

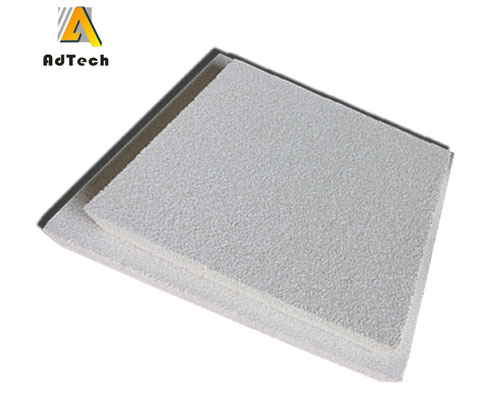

Ceramic foam filter filtration technology is a research hotspot in the removal of inclusions in recent years. Use microporous refractory materials to develop a porous ceramic filter with strong chemical stability and strong adsorption capacity, and then install it in the tundish. When the aluminum liquid flows through the ceramic filter, the holes on the filter will squeeze the aluminum Change the flow field structure to force the inclusions to separate from the molten aluminum and move to the wall of the hole, and then be adsorbed and removed by the ceramic filter. This removal process mainly relies on the adsorption of microporous refractories to the inclusions, and the buoyancy of the inclusions is not much affected. Therefore, the removal effect of small-size inclusions can be effectively improved.