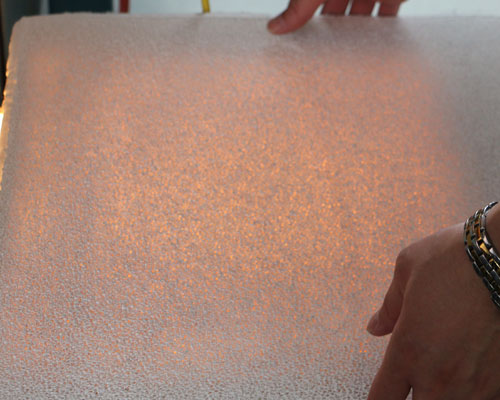

The ceramic filters for metal casting can effectively remove the large impurities in the molten aluminum and absorb the micron-level fine particles of impurities, thereby improving the surface quality, improving the product performance, improving the microstructure and increasing the output. Ceramic filters for metal casting are widely used in the production of aluminum profile, aluminum foil and aluminum alloy.

Ceramic Foam Filter Manufacturing Process

The ceramic foam filters for metal casting adopt a three-dimensional network structure, and use the organic foam sponge connected with the pores as a carrier to immerse it in a special ceramic slurry with thixotropy, and uses a special roll extrusion process to uniformly distribute the ceramic slurry Apply on the surface. The backbone of the carrier. Then, it is dried and cured, and then fired at high temperature.

Porosity is the percentage of the total volume of the cavities in the foam ceramic filter product relative to the total volume of the filter. The porosity determines the filtration capacity of the ceramic foam filter per unit volume. The greater the porosity, the greater the filtering flow of the filter, and the stronger the filtering capacity.

At present, there are two main methods to calculate the volume of the holes for ceramic filters:

One method is to calculate the volume of the holes on the foam ceramic filter according to Archimedes’s law, that is, use an overflow pipe to pour water into a glass beaker until the water flows out of the overflow pipe, and then test the water. Water no longer flows out. Put all the samples in the water gently, then the water flows out of the overflow pipe, and measure the amount of water in the part. Subtract the volume of overflow from the physical volume of the filter plate, which is the total volume of the wells in the filter plate. volume.

Another method is to determine the true density and bulk density of the sample to be tested, and then calculate the porosity of the sample according to the following formula.

Both methods have their advantages and disadvantages. The operation method is simple and convenient, and the detection speed is fast, but its fatal disadvantage is the water absorption characteristics of the filter plate material itself, so the amount of water discharged is less than the actual amount of water. This results in too small measurement data.

Although the test process of the second method is more complicated, the influence of the water absorption rate of the filter plate material is excluded during the test, and the data obtained is relatively accurate.

In this standard, the porosity index is determined to be greater than 84%.