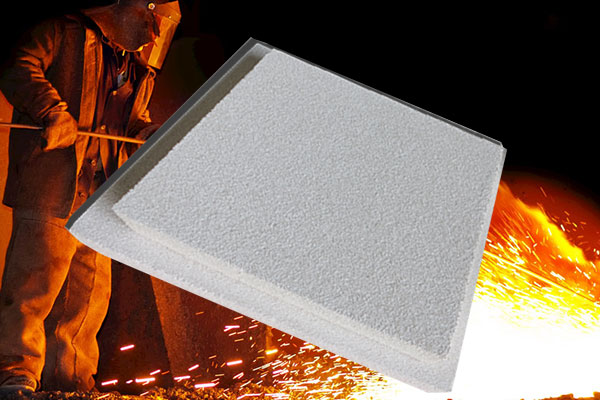

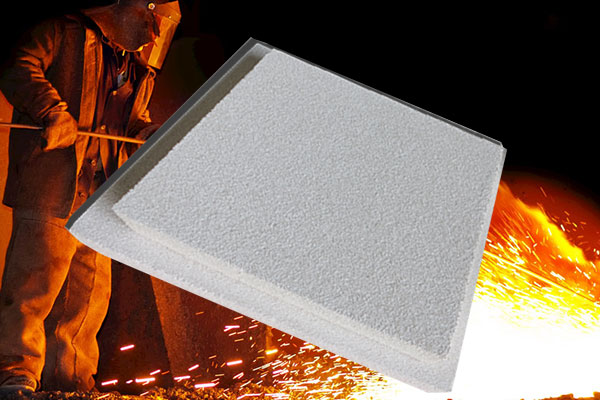

Ceramic Foam Filter For Secondary Aluminum is used to filter impurities in molten aluminum alloy to meet the high value-added, high-tech performance aviation, transportation, and other aluminum alloy precision casting production.

When the fluid passes through these filter micropores, the suspended matter, colloidal particles and polymer organic matter are captured or adsorbed in the micropores inside the road, so as to achieve the effect of purification and filtration uniformity.

Ceramic Foam Filter For Secondary Aluminum can effectively remove harmful impurities such as bubbles, ash oxides and various inclusions in the aluminum melt, thereby fundamentally eliminating air holes, slag holes, and blisters in castings, greatly improving the yield and quality of castings.

Most of the aluminum castings are secondary aluminum. In 2015, my country’s secondary aluminum output was 5.75 million tons. In 2015, my country’s total automotive secondary aluminum production was 2.6 million tons, accounting for 45.2% of secondary aluminum output. It is the largest application field of secondary aluminum.

The main products of my country’s secondary aluminum enterprises are aluminum alloy ingots and aluminum alloy liquid for automobiles. The downstream customers are concentrated in the automobile industry, and their main customers are automobile or component manufacturers. The production and operation of enterprises are closely related to the prosperity of the automobile industry.

Recycled aluminum for automobiles faces new challenges. In recent years, with the popularization of new energy vehicles, the application of aluminum in automobiles has changed. With the increasing popularity of electric vehicles, the amount of aluminum used in automobile engines and transmissions will decrease year by year, and the amount of aluminum used in battery packs, body covers, and motor housings will increase significantly. This trend is also applicable to my country.

With the advancement of automobile electrification, the demand for reclaimed aluminum in the important consumer areas of fuel vehicle engine cylinder blocks, cylinder heads, and gearboxes has decreased, while the new aluminum parts used in electric vehicles, such as battery packs, rarely use reclaimed aluminum. Therefore, the proportion of aluminum castings, including secondary aluminum, in automotive aluminum may be reduced.

Deep bed filters can better filter micron-level impurities and filter more pure aluminum liquid. Because the tube wall has a micron pore size, it is easy to block, so you must first use a ceramic foam filter to remove larger particles in the aluminum liquid. This is a true way of using high-end aluminum products.