Ceramic foam filters for aluminum casting filtration mechanism usually described as interception, sediment layer and deep filtration.

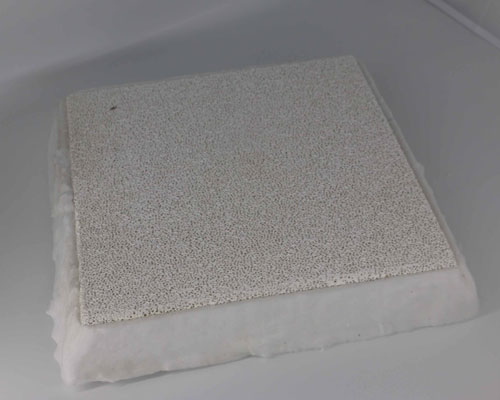

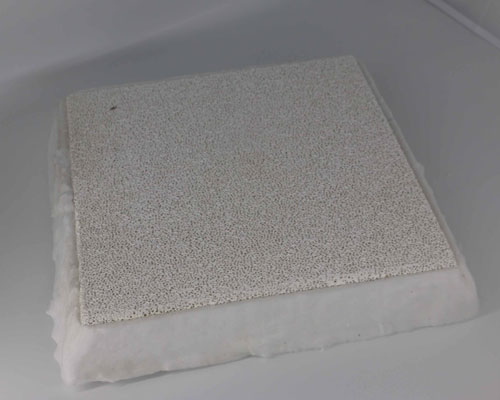

Ceramic Foam Filters for Aluminum Casting

1. The effect of a sludge layer or filter cake layer, with deposition of particles in the melt and intertwined and curved mesh joints, improves the ability to capture phase particles.

2. The rough surface formed by the mesh truss surface gap increases the interface between the aluminum liquid flow and the solid ceramic surface to promote particles in the aluminum liquid flow.

The direction of the auxiliary flow is more disordered, which aids in the collection and settling of solids.

3. Due to microscopic cracks and pinholes on the surface of the mesh frame, a fluoride flux with a strong affinity for particles such as Al2O3 is pre-deposited.

The whole filter cake effect and strong chemisorption force increase the ability to capture trapped heterogeneous particles.

The liquid aluminum ceramic foam filter is the most widely used filter in the field of filtration of molten aluminum. The advantage is high porosity, high filtration efficiency, ease of replacement, low cost, manufacturability; a part of liquid inclusions can also be separated by filtration of solid inclusions.

The modern process of purification of molten aluminum, the filter is close to the completion of the last cleaning process of the casting.

Prior to this, after flux refining in the furnace, standing, medium and adsorption without medium, although 60% to 80% of inclusions and gas have already been removed, but the melt was still dispersed with finer (grain diameter usually <15 μm) (including inclusions of secondary raw material in the chute and intermediate production contract).

To obtain high quality aluminum products, we must ensure that these small inclusions are collected and separated by adsorption.

Compared to other purification methods, the filtration method has become the preferred method for the final purification of molten aluminum due to its low energy consumption, ease of operation, high purification efficiency, and less secondary pollution.