The degassing method of aluminum is to reduce the hydrogen (gas content) in aluminum melt before casting, which is one of the most important parts of foundry quality control.

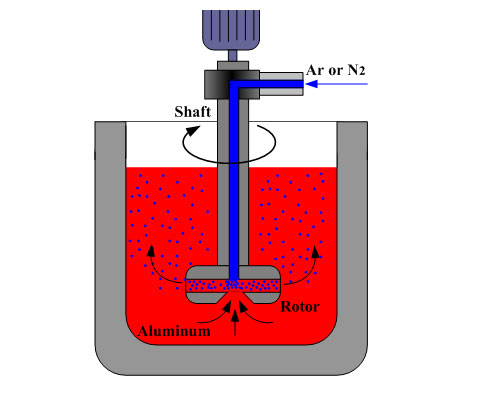

The degassing unit for molten aluminum is placed between the holding furnace and the casting machine. Nitrogen is blown into the molten aluminum alloy and then chopped up through a rotating graphite rotor in the degassing tank. Then, a large number of dispersed bubbles are formed, which makes the liquid aluminum alloy fully contact with nitrogen in the treatment tank. According to the principle of pressure difference and surface adsorption, the bubbles absorb hydrogen and oxide slag. Then bubbles rise to the surface of the melt to form scum. Then, the molten aluminum alloy flows from the outlet of the degassing unit to the casting machine to purify aluminum alloy.

The process of removing hydrogen is called degassing. One of the most effective degassing method of aluminum is to use inert dry gas nitrogen for rotary inert degassing. The key of rotary degassing is that the rotor can break the large bubbles of inert gas that enters into very small bubbles, and make them diffuse in the entire molten metal. By reducing the bubble diameter, the surface area of the inert gas is increased sharply, so that more inert gas surfaces are in contact with the hydrogen and impurities in the molten metal and the hydrogen or impurities are removed from the molten aluminum as the bubbles rise.

Degassing Principle

The dissolved hydrogen will move from the high concentration region (in the melt) to the low concentration region (in the inert gas). Hydrogen will be dispersed in the molten metal as it is released in any confined space. It will maintain a constant concentration throughout the melt. The migration rate of hydrogen in molten aluminum is almost as fast as that in air. Therefore, it is not necessary to expose each ounce of metal to inert gases.

The efficiency of aluminum degassing depends on two factors: the transport rate across the metal / gas interface and the total surface area that can be transported.