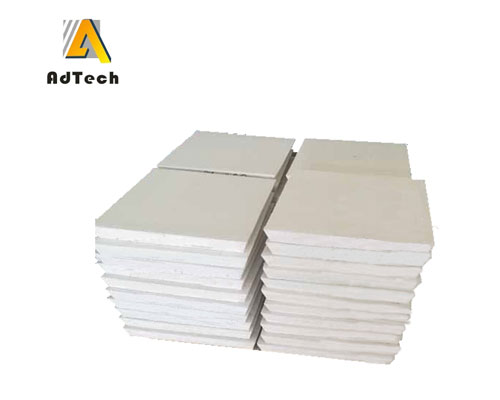

Foam ceramic filters for aluminum generally use polyurethane foam as a carrier, filled with a ceramic slurry made of refractory aggregate sintering aids, binders and other micropowders and water, and then extrude the slurry, and the rest is covered in the foam The ceramic material around the fiber is dried, baked and sintered at a high temperature, and the polyurethane is decomposed by heat, leaving a foamy ceramic product, that is, a foam ceramic filter. AdTech has a ceramic foam filter production line, it improves productivity and reduces cost.

The ceramic material used for molten metal filtration has a very high melting point and will not melt during casting or decompose into molten metal.

Filter Specifications

The number in front of PPI represents the hole density of the product. If the model is 10ppi, it means that the uniformity of pores on any 25.4mm length is 8-12.

Generally, 10ppi is used for casting ductile iron, 10/20ppi for gray iron, 20/25ppi for cast aluminum, and 25/30ppi for cast copper depending on the cleanliness of the solution.

Filter Mechanism of Ceramic Foam Filters for Aluminum

• Sieving. Like a sieve, it prevents the inclusion of particles and their agglomerates whose size is larger than the pore size of the filter surface.

• Cake filter. After sieving, many inclusions larger than the filter hole are captured at the inlet end of the filter. As the number of captured inclusions increases, a “filter cake” composed of large inclusions is formed on the surface of the inlet end of the filter. The “filter cake” makes the liquid thinner, so that the inclusions smaller than the pore size of the filter are also partially captured on the “filter cake”.

• Deep bed filtration. Inside the ceramic foam filter, the path that the melt flows through is tortuous, and there are even cross-flow foldbacks in a small local area. This mainly plays two roles: ①It can greatly increase the probability of the inclusion particles contacting the filter; ② Speed up the flow rate and flow direction change of the melt, so that the small inclusions in the melt can be caught in a corner after being collided.