How to use ceramic foam filter (CFF) molten metal filtration is important for molten aluminum filtering. Alumina ceramic foam filter molten metal filtration is used for the filtration of aluminum and aluminum alloys in foundries. It can effectively remove inclusions, reduce residual gas and provide laminar flow, and then the filtered metal is significantly cleaner. Clean aluminum melt can produce higher-quality castings, less waste, and fewer inclusion defects.

How to Use Ceramic Foam Filter for Molten Metal Filtration

(1) Prepare the CFF filter box. CFF filter box shall be thoroughly cleaned before use to prevent refractory residues left during previous use from falling into molten aluminum. The size of the CFF filter and filter box shall be matched, and the matching gap and deflection angle between them shall be as small as possible. Fix a fiber paper gasket on the beveled edge to provide a lateral compressive load to secure the filter in the filter box and prevent metal from bypassing the filter edge.

(2) After cleaning the CFF filter box, apply a layer of fire-resistant coating on the inner surface of the filter box, and then gently lay the filter flat.

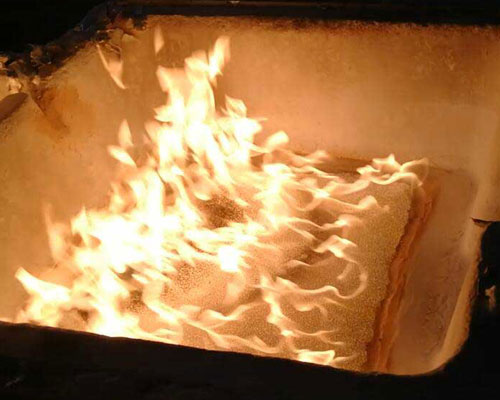

(3) Proper preheating is an important part of ceramic foam filter uses. Improper preheating methods usually lead to the following problems: cracks appear during preheating.

The size of the ceramic foam filter plate is also important for molten metal filtration. In addition to the actual production requirements of aluminum product quality, we should also consider the flow rate of aluminum in the washing tank, the total amount of filtration, the cleanliness of aluminum itself, and the production cost. Choosing a high specification foam ceramic filter board will increase production cost and reduce production efficiency.

Ceramic foam filter molten metal filtration technology can not remove 100% inclusions in liquid aluminum. If all the inclusions in liquid aluminum are filtered out, the effective nucleation will be reduced during solidification, which will affect the solidification time and the structure after solidification.