Launder for Casting Molten Aluminum cross section is a U-shaped opening and widening upwards, the molten metal flows in the launder structure. The inner surface of the launder in contact with the molten metal is defined by a refractory material, such as a ceramic wear-resistant composition.

The refractory material forms a flow channel for the molten metal, which is preferably an upwardly widening groove with a circular bottom. The size of the flow channel is determined so that under normal operating conditions, the upper surface of the flowing molten metal extends to a height of 10% to 20% of the total height of the flow channel. The casing of the launder is made of metal, such as steel. When producing ceramic linings, the steel shell is used as a mold for easy transportation to the installation site.

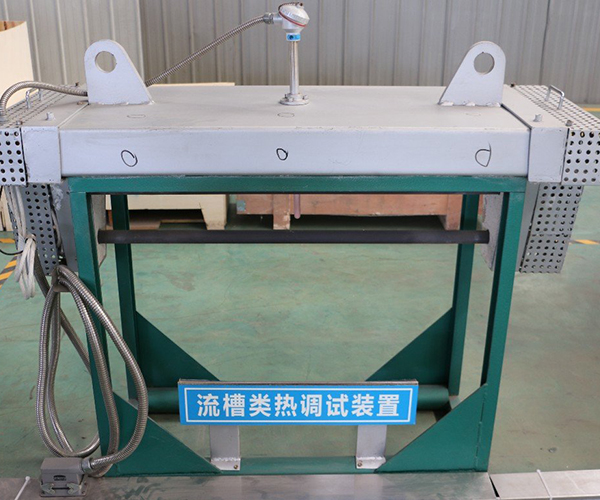

The Launder for Casting Molten Aluminum includes a metal shell forming the outer surface of the bottom of the launder, a refractory lining defining a flow channel for molten metal, and an insulating layer arranged in between. Refractory lining and metal shell, the thermal insulation performance of the thermal insulation layer is much better than that of the refractory lining.

The refractory lining of the aluminum casting launder is a separate element that can be disassembled and replaced as an integral part, so that the insulation and the steel shell remain installed in place. In this case, ceramic wool separates the composite from the steel sleeve, and the composite can be easily replaced. The compound is anchored to the steel shell by screws. The anchor screw is screwed to the nut that has been cast in the composite through the steel shell and the insulating material.

The thickness and thermal insulation capacity of the thermal insulation layer provided between the refractory lining and the outer shell of the launder and trough are appropriately selected to provide a preferred temperature gradient for the refractory lining. The preferred insulating material is ceramic wool insulating material. The importance of the insulating layer is essential, because without it, the heat loss is too great, and the power required to heat the resistor will melt the resistor itself. On the other hand, if the insulation is too good, the molten metal will penetrate into the ceramic refractory compound, resulting in leakage of the launder.

The refractory launder cover is arranged on the top of the launder, so that no large amount of gas can be discharged to the outside from between the cover and the launder, and there is no heat loss flow through radiation or gas. The surfaces of the cover and the launder placed against each other are substantially flat, whereby the launder continuously supports the cover at its long edges substantially over its entire length.

The cover of the sink structure includes a metal cover, a resistor (used to heat the lower part of the launder), and an insulating layer to prevent heat loss due to radiation through the metal shell. The heating resistor is located above the flow channel of the launder, so that the heat from the resistor radiates to the metal and refractory lining flowing at the bottom of the launder.