The filtration of molten cast metal has proven to be an effective method to improve overall casting quality. Filtration improves the mechanical and physical properties of the casting by removing inclusions from the molten metal before it enters the mold cavity.

There are many applications in casting practice, where a large amount of molten metal is repeatedly poured into the holding furnace to replenish the metal used, and poured into the die-casting machine each time it is cast and during pigging operations. Those foundries that need to repeatedly or automatically pour molten metal (especially aluminum) into casting machines such as die casting machines and permanent mold operations cannot easily use filters in their gate systems. Therefore, it is common to filter the metal in the immersion well of the holding furnace before pouring the metal into the machine. These operations usually use a robot to dip into a furnace dipping hole and then pour the metal into a casting machine. Aluminum is usually the metal cast in these operations. Even if the aluminum is filtered in the holding furnace, when it is immersed in the air into the immersion hole, the aluminum will immediately form scum or oxide. Being able to filter the metal as it is poured into the casting machine would be a huge advantage. Most of these operations are also high-volume.

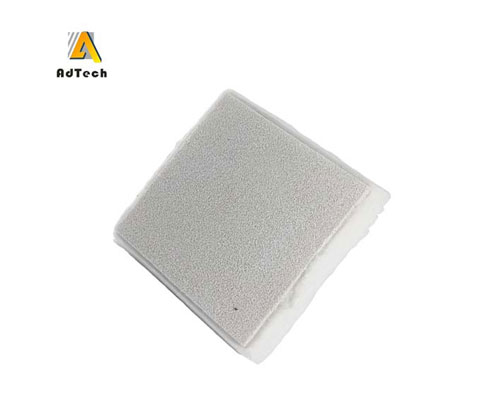

Ceramic foam filters are widely used in molten cast metal filtration to improve the cleanliness of the castings, and reduce the number of castings that must be scrapped due to the presence of undesirable impurities. This ceramic filter is usually incorporated into the gating system to remove slag, dross, and other particles from the metal stream before the metal enters the mold cavity. The most common types of ceramic filters include rigid porous ceramic structures and rigid reticulated ceramic foams. These filters are relatively thick, and due to their bulky structure, the first molten metal that often cools to reach the filter requires thicker openings to ensure reliable passage of molten metal. The honeycomb extruded ceramic filter therefore relies on forming a filter cake on the upstream side of the filter to remove smaller inclusions that would otherwise pass through the open filter. The ceramic foam filter, while providing a more tortuous path than the honeycomb filter, also presents the formation of filter cakes that can become inclusions.