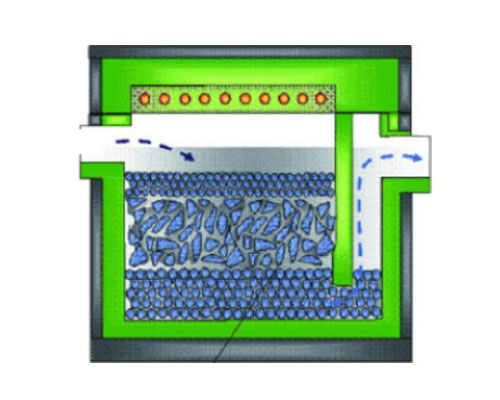

The molten metal deep bed filtration depends on the tortuous path through which the melt must flow. The molten metal deep bed filtration efficiency is inversely proportional to the size of the filter particles and directly proportional to the depth of the filter bed. Inclusions are deposited both on the particles and in the gaps between the filter media. And they may be scattered in part or all of the filter space. Therefore, the filter has a large surface area for trapping inclusions, and can trap particles whose size is much smaller than the pores of the filter bed.

The widespread use of aluminum alloys in high-end applications such as casting, extrusion, and rolling will never make efforts to improve melt quality obsolete. Therefore, more companies will have to catch up with the current state of the art. Downstream industries also provide a strong impetus for further improvements and new developments.

The impurities in the melt were identified as the main cause of product failure during production and use. Therefore, melt cleanliness becomes a measure of melt quality. Two main types of impurities can be distinguished: (1) dissolved elements and (2) suspended particles. The source of impurities can be traced back to the original metal, various melt processing operations, and the interaction of the molten metal with refractory materials and the environment. Essentially, the melt quality can be controlled by removing alkali trace elements, H and inclusions. Various technologies, such as online degassing equipment, in-furnace flux, and deep bed filtration equipment, and ceramic foam filters, can be used to control impurity levels.

Regardless of the type of filter used, care must be taken to ensure that the filter is not affected by excessive vibration or changes in the metal level. These “disturbances” will cause the release of inclusions, which may eventually lead to inclusions in the finished product. Good process control downstream of the final filtration equipment is especially important. If repairs are required, this should include careful cleaning preparations and special attention. In addition, operators in the foundry should take care to minimize turbulence in certain areas, such as turbulence around metal distribution bags.

Even with the best available filtering technology, the very dirty metal input will overwhelm you. Therefore, the importance of the correct treatment of metals before filtering cannot be overstated. The cleaner the metal entering the filter, the finer the filter that can be used, resulting in “even cleaner” metal leaving the filter.