Aluminum foil has a series of advantages such as light weight, airtightness, good coating, non-toxic and moisture-proof, so it is widely used in the national economy and people’s daily life. It is currently mainly used in packaging, transportation, and construction. Aluminum foil factories generally use the casting and rolling method to produce billets. To produce double zero aluminum foil with thinner thickness, fewer pinholes, better mechanical properties, and surface quality, higher requirements are put forward on casting and rolling technology and purification treatment of aluminum melt.

Studies have shown that the presence of hydrogen and inclusions in the electrolytic aluminum liquid can easily cause defects such as slab cracks, bubbles, slag inclusions, and coarse grains. In order to produce aluminum foil with thinner thickness, fewer pinholes, better mechanical properties, and surface quality, it is necessary to strictly control the casting process and purification treatment of aluminum melt.

Production Control of Aluminum Melt Quality

Aluminum Liquid Cooling Treatment: In order to reduce the influence of high-temperature electrolytic aluminum liquid on product quality during the casting and rolling production process, a certain amount of solid material is added to the alloy in the melting furnace to reduce the temperature of the alloy melt. After adding a certain proportion of solid materials, the melting temperature of the alloy melt is generally reduced to the range of 720-760℃.

Purification Treatment of Aluminum Melt

The electrolytic aluminum liquid is cooled by adding some solid materials to reduce the content of hydrogen and slag, and further purification of the melt is still needed. Because the double zero foil has strict requirements on the internal structure, surface quality, chemical composition, and mechanical properties of its blanks, no defects such as air passages, slag inclusions, and cracks are allowed, and the grain size must be level 1. Therefore, a series of effective degassing and slag removal measures must be taken for the melt before casting and rolling.

Purification treatment in the furnace: The aluminum melt purification treatment method in the static furnace adopts the refining agent refining process. During the refining operation, the refining temperature should be 735℃, and the refining time should be 15min. After refining, the slag is removed and the Na-free covering agent is used for melt protection.

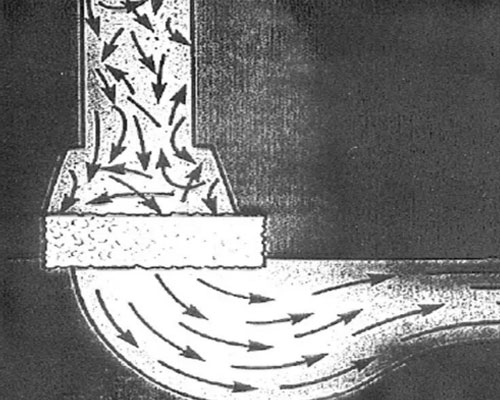

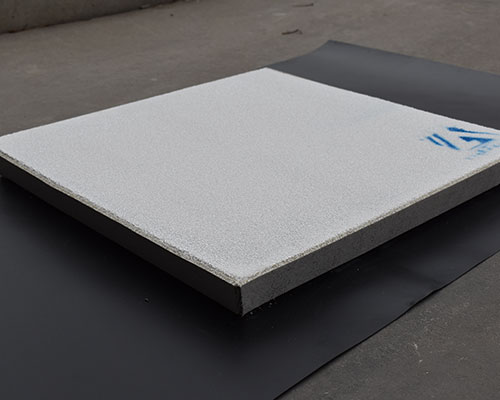

On-line purification treatment of melt. Although the aluminum melt undergoes a series of furnace purification treatments, the degree of purification is limited. After refining in the furnace, a certain amount of gas and oxide inclusions remain in the melt. In order to produce high-quality double-zero aluminum foil blanks, a purer aluminum melt must be obtained. The online continuous degassing device adopts a box type, and uses high-purity Ar gas to rotate and spray into the molten aluminum through two graphite rotors to achieve melt purification. The online melt filter device adopts box filter mode, and the filter plate adopts foam ceramic material.