Argon gas (containing a small amount of chlorine gas) is introduced into the online rotary degasser unit to remove the gas in the melt. The aluminum melt is sequentially filtered through a ceramic filter and a deep bed filter to remove non-metallic solid inclusions in the melt.

Rotary nozzle inert degassing method is a kind of treatment device for aluminum melt outside the furnace. This rotary degasser unit is equipped with a graphite gas rotating nozzle in the reaction chamber, and the gas passes through the rotor of the nozzle to form dispersed fine bubbles. At the same time, with the melt agitated by the rotor, the bubbles are evenly dispersed in the entire melt, thereby producing the purification effect of exhaust and slag removal.

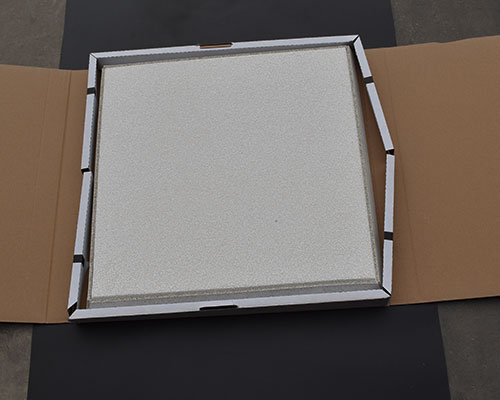

The ceramic foam filter plate is made by injecting the mixed slurry of alumina and phosphate into the sponge plastic, and then drying and sintering to volatilize the sponge plastic. It can also be called a microporous mesh foam ceramic sheet with a sponge-like structure.

Foam ceramic filter plate is easy to use, has good filtering effect, low price, and is widely used all over the world. More than 50% of aluminum alloy melts in developed countries are filtered by foam ceramic filter plates.

The deep-bed filter adopts a metal box structure with a high-performance thermal insulation lining inside and a refractory cast lining. The box is sealed by the upper heating cover, which also preheats the filter. The box body is generally composed of two cavities, the inlet cavity is equipped with a filter layer, and the filter layer is supported by a grid.

The filter bed is composed of many layers of alumina balls and gravel layers. The selection of filter material size and the distribution of different layers play a key role in optimizing the filtering effect and prolonging the life of the filter layer.

During use, the filter is heated and insulated by the upper and lower heating devices, which can maintain a longer service life of the filter, and the cast metal can reach more than 7000t. Therefore, the deep bed filter is suitable for the production of aluminum alloys in larger batches.