Using Alumina Ceramic Foam Filter Instructions for Aluminum Casting

Inspect and clean the surface of the CFF filter box, keep it clean and intact.

Gently lay the filter in the filter box, press the sealing gasket around the filter by hand to prevent molten aluminum from dispersing or floating away.

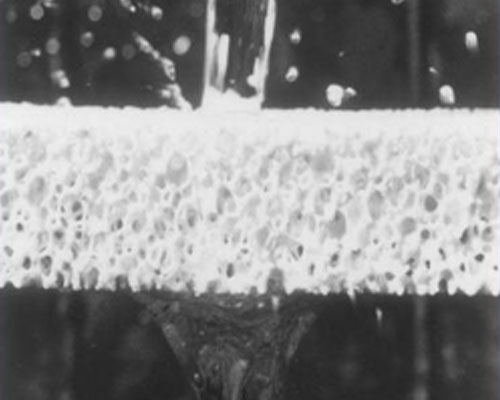

Use electric or gas burning to preheat filter box and ceramic foam filter evenly for 15-30 minutes, make sure their temperature close to molten aluminum. The preheating temperature for the ceramic foam filter should above 260℃. Expanding cotton will seal after preheating.

This procedure makes ceramic foam filter steady fixed in molten aluminum. Preheating also leads ceramic foam filter pores to open and avoids occlusion caused by thermal expansion and contraction.

Observe the change of molten aluminum height, hold molten aluminum flow in standard needs. Normal starting molten aluminum height is 100-150mm. The height falls down below 75-100mm when molten aluminum flows, and it will slowly increase later.

Do not hit or shake the ceramic foam filter in the filtration process. At the same time, control the molten aluminum flow rate in launder, never to be too much or too little.

Take out alumina ceramic foam filter and clean filter box in time after filtering.

Alumina Ceramic Foam Filters Feature

- 3D reticulate structure

- High mechanical strength, no-dregs off when flapping

- High porosity

- Large surface areas, strong absorptivity of impurities

- Excellent thermal shock resistance

- Rapid improvement in yield

Using Alumina Ceramic Foam Filter Application

1. Aluminum alloy bar choose: 10-30ppi

2. Long-term casting choose: 30-50ppi

3. High quality aluminum profile or plate choose:40 or 50ppi

4. Double zero wave continuous casting and rolling choose: >50ppi

5. Other specifications can be customized as your requirements

Alumina ceramic foam filter can effectively remove and absorb large or small impurities in molten aluminum, improve the surface quality, product performance, and microstructure effectiveness. Mainly used in the domestic, construction, electricity, condensing tubes, cable and other aluminum alloy precision casting.