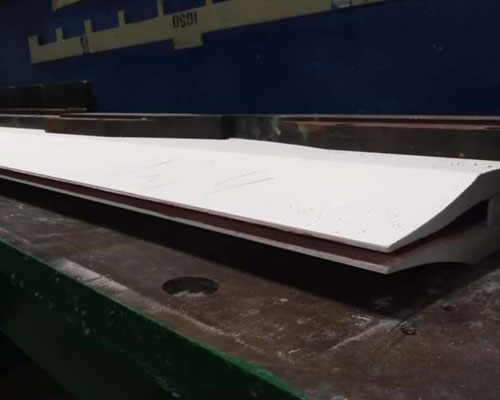

The casting nozzle cavity is composed of ceramic fibers and inorganic ceramic materials, and has the advantages of moderate elasticity, small deformation and long service life.

It can effectively prevent the molten aluminum from corroding the nozzle cavity of the casting mold, thereby providing an effective guarantee for the quality of the cast-rolled aluminum plate.

According to customer requirements, feed tips and nozzles of various types and supply methods can be manufactured.

According to the boundary layer theory of fluid mechanics, after the aluminum melt enters the nozzle cavity, under the action of the static pressure of the liquid surface in the front box, it flows along the nozzle outlet direction with the least resistance.

The flow velocity in the center area away from the nozzle boundary is greater than that in the boundary area, and a shunt block must be set inside the nozzle to ensure that a part of the melt flows to both sides after encountering resistance in the middle.

During the casting and rolling process, the melt flow in the cavity is required to be stable, and the melt heat flow field at the nozzle outlet is uniformly distributed in the width direction, so the shunt blocks must be reasonably distributed.

High-Speed Thin Strip Twin-Roll Casting

High-speed thin strip twin-roll casting is a short-flow near-net shape processing technology. The casting-rolling process belongs to the sub-rapid solidification category, and its cooling rate is between 102°C/s and 104°C/s.

This technology particularly has the advantages of refining crystal grains and suppressing segregation, can improve the microstructure of the product, bring excellent subsequent processing performance, and can produce products that are difficult to produce under conventional process conditions.

Due to its technical characteristics, this technology requires rapid cooling of molten metal during casting and rolling, and a reasonable flow field in the nozzle cavity, otherwise it will lead to the quality of thin strip products and the stability of castings and castings. The rolling production process is difficult to guarantee.

The structure and components of the nozzle cavity are the key components that affect the flow field and temperature field distribution in the nozzle cavity. Therefore, it is necessary to develop a new type of mold nozzle, which has a stronger cooling capacity and a more reasonable flow field distribution in the nozzle cavity.