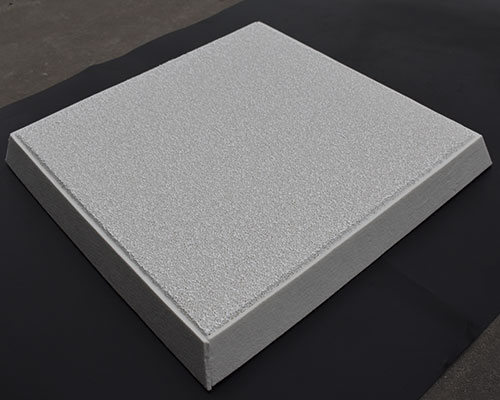

The alumina ceramic foam filter is suitable for the filtration and purification of aluminum and aluminum alloys. It is composed of alumina, silica, talc, and kaolin to form a ceramic powder, and then adds polyvinyl alcohol, silica sol, and water to prepare a slurry. The polyurethane foam is used as the carrier, impregnated with the above slurry, and extruded to form a blank. The blank is placed in a drying box and dried and hardened at 100-110°C. After drying, the blank is put into a sintering furnace, and the temperature is raised to 1350-1400 °C for high-temperature sintering to obtain an alumina foam ceramic filter.

Alumina ceramic foam filter has good high temperature stability in aluminum alloy melt, does not pollute the alloy, and has good filtering and adsorption capabilities for oxide inclusions and flux inclusions in molten metal. The ceramic foam filter has good filtering and purification effect, small heat capacity, low resistance to fluid, and large filtering capacity. After the filtration and purification test of aluminum and aluminum alloy, the performance is good.

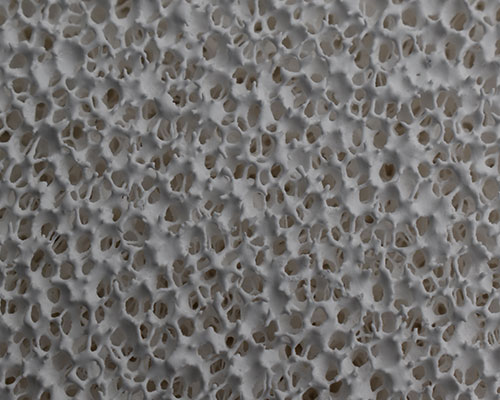

Due to the unique three-dimensional network structure, the alumina foam ceramic has special filtering and purification mechanism (mechanical interception, exhaust rectification scum, and deep absorption of fine slag inclusions).

The purification effect of the foam ceramic filter is incomparable with the refractory fiber filter and the honeycomb straight hole ceramic filter. It is characterized by a uniform rigid framework structure and a small dispersion in the mass of the filtered molten metal. The alumina ceramic foam filter is suitable for filtration accuracy is good.

The ceramic foam filter can not only filter out most of the tiny solid suspended inclusions as small as a few microns in the molten metal, but also filter out the liquid slag and gas. The use of ceramic foam filters to filter molten metal liquid can also make the flow rate of the liquid metal become slow and orderly, greatly improve the microstructure and mechanical properties of the casting, improve the quality and compactness of the casting, and reduce the wear of the tool during the cutting of the casting.

Practice has proved that the filtration efficiency of the foam ceramic filter is as high as 75-97%. Therefore, ceramic foam filters have been widely used in the purification of aluminum, copper, and steel melts, and are favored by more and more metallurgical and foundry enterprises.