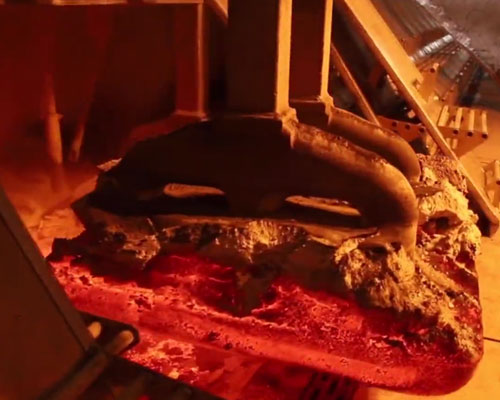

Due to the high content of non-metallic inclusions, hydrogen, and sodium in the electrolytic aluminum liquid, the direct batching of 8079 aluminum alloy cast-rolled plates with electrolytic aluminum liquid will inevitably cause serious metallurgical defects. Therefore, the electrolytic aluminum liquid is pretreated with a special device before the electrolytic aluminum liquid is put into the furnace. In the aluminum pretreatment process, the refining agent reacts physically and chemically with the hydrogen, sodium and various non-metallic inclusions in the melt, so as to achieve the purpose of preliminary sodium removal, hydrogen and impurity removal, so that the electrolytic aluminum liquid can be purified.

Aluminum Pretreatment Process

In order to minimize the oxidative slagging and gas absorption tendency of the electrolytic aluminum liquid into the furnace, reduce the oxidation slagging of the electrolytic aluminum liquid and a large amount of air entrapment, and maintain the pretreatment effect of the electrolytic aluminum liquid.

During the smelting of 8079 aluminum alloy, the added charge must be clean, dry, and oil-free to reduce the oxidation slagging and hydrogen absorption of the melt during the smelting process. Use Al-Si and Al-Fe master alloys instead of Si and Fe agents to adjust the content of Fe and Si, because the impurity content in the metal additives is much higher than that in the master alloy, and the combustion promoter and detonator in the metal additives are in the aluminum melt Local exothermic reaction occurs in the aluminum melt, which can ignite the alumina slag around the aluminum melt, and the temperature of the slag is as high as 2024 ℃, which will cause severe local overheating of the aluminum melt, which is extremely unfavorable for the control of the grain size of the cast-rolled sheet.

In order to reduce the content of Na, [H], and inclusions in the melt and reduce the pollution to the holding furnace, the 8079 aluminum alloy melt is pre-refined with AdTech refining agent in the melting furnace. AdTech online degassing device is used for online degassing of 8079 aluminum alloy melt, and the hydrogen content should be controlled not higher than 0. 11 ml /100 g Al. Use 30 ppi /50 ppi matching foam ceramic filter device for filtration.