Aluminum refining process includes two aspects: removing hydrogen inside the furnace and on-line degassing outside the furnace. For the AA5182 large-scale Al-Mg alloy ingots, the hydrogen removal in the furnace is mainly done by solvents, and the online removal of hydrogen outside the furnace mainly uses an online degassing system. Through the rotation of the graphite rotor, the inert gas enters the aluminum liquid through the graphite rotor and rotation of the molten aluminum stirs and smashes the bubbles to improve the efficiency of hydrogen removal.

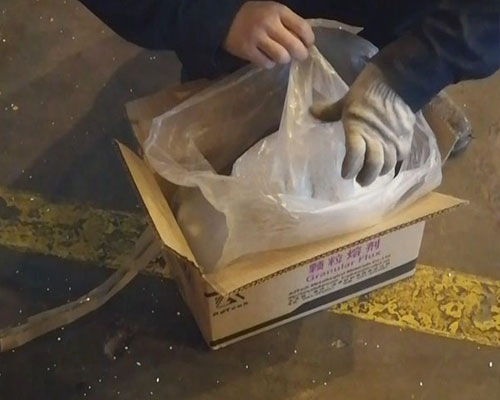

The method of aluminum refining in the furnace includes adding refining flux to the surface of the molten aluminum in the holding furnace, and passing inert gas into the molten aluminum. The chemical composition of refining agent mainly includes: NaCl, NaF, KCl, KF, AlF3, etc. When in-furnace refining is carried out in a holding furnace, a gas spray gun can also be used to pass inert gas into the molten aluminum for refining, but the door of the holding furnace needs to be opened during operation, and the heat is lost to the outside of the furnace. It is difficult for operators to operate under high temperature conditions, and it is difficult to carry out refining for a long time.

The on-line aluminum refining outside the furnace mainly adopts the method of inert gas rotating injection. The inert gas is mainly Ar. Although N2 can also play a certain refining effect, because N2 and high-temperature aluminum liquid can produce chemical reactions to form nitrides, aluminum The oxide film on the surface of the liquid is destroyed, reducing the effect of hydrogen removal. Especially when the temperature of molten aluminum reaches 780C or above, the chemical reaction becomes more obvious. Therefore, for the A-Mg alloy, the inert gas used for hydrogen removal is mainly Ar.

Using an online degassing system, the graphite rotor is rotated and sprayed with inert gas to pass Ar into the graphite rotor, the graphite rotor is immersed in the aluminum liquid, and the graphite rotor rotates while stirring and crushing the sprayed Ar bubbles. In the process of bubbles floating, the hydrogen in the molten aluminum is absorbed into the bubbles due to the partial pressure difference of hydrogen inside and outside the bubbles, and removed as the bubbles float to the surface of the molten aluminum. For the alkali metals contained in the aluminum liquid, in order to remove the alkali metals at the same time, a certain proportion of Cl2 and Ar are mixed together and passed into the aluminum liquid. When the AA5182 large-scale Al-Mg alloy is cast, the flow rate of the aluminum liquid reaches 40t/h. Therefore, this paper uses a 3-rotor hydrogen removal device to improve the efficiency of hydrogen removal and the flow rate of molten aluminum.

In order to improve the aluminum degassing refining effect, the on-line degassing unit has been improved in two aspects: one is to extend the running path and running time of the gas in the graphite rotor to improve the preheating effect of the inert gas Ar in the graphite rotor. The second is that during the design process of the refining tank, the inner wall of the refining tank is designed with a larger inclination angle. As the liquid level of the aluminum liquid in the refining tank increases, the cross-sectional area of the refining tank increases accordingly, so that it can interact with the inert gas bubbles. The degree of expansion matches each other to prevent bubbles from fusing together and improve the effect of hydrogen removal.

AA5182 large-scale Al-Mg alloy aluminum refining process, whether it is the removal of hydrogen in the furnace or the removal of hydrogen outside the furnace, the inert gas N2 or Ar is used. At the same time, in order to remove the Na in the aluminum liquid, a small amount of Cl2 is required for refining effect. For. Since the refining process of C2 has both physical refining and chemical refining, Cl2 can dry the inclusions in the aluminum liquid, and the inclusions and the aluminum liquid are easily separated, which is conducive to the subsequent removal of inclusions. The refining effect is the best. However, because Cl2 is very toxic, harmful to human health, deteriorating the ecological environment, and has a strong corrosive effect on refining equipment, tools, workshops and other equipment, so now it is almost not necessary to use pure Cl2 to refine aluminum liquid, but a certain proportion of Cl2 Refined gas, such as Ar or mixed use, to improve the effect of hydrogen removal.