How to improve the quality of the molten aluminium and effectively remove the inclusions such as hydrogen and aluminum oxide, the key is the refining……

The production process of double zero foil casting and rolling is: electrolytic aluminum liquid + solid waste smelting → standing → refining → online refining……

Most of the casting and rolling manufacturers use high-purity argon or nitrogen as the carrier for refining, and purify the melt by blowing fluxes into……

The purity of aluminum melt is one of the main factors that affect the pass rate of aluminum foil. The slag inclusions in the aluminum……

At present, the most widely used ceramic plate filter device, but its independent application in high-end products has greater limitations. Generally, ceramic plate filter device……

The quality of cast-rolled aluminum strip is generally related to the processing accuracy, configuration, and quality of auxiliary materials of the equipment itself. It mainly……

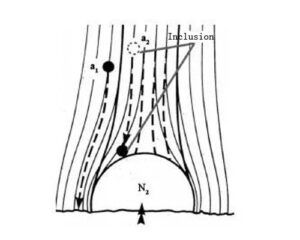

Argon gas (containing a small amount of chlorine gas) is introduced into the online rotary degasser unit to remove the gas in the melt. The……

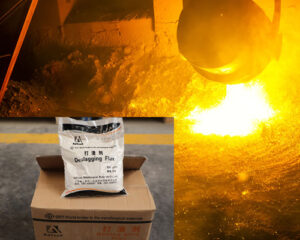

Impurity removal by fluxes is an important method for purifying aluminium melt. At present, there are many types of fluxes developed and used at home……

Fluxes for Aluminium Melting can remove hydrogen, oxides, and other impurities. According to different uses, Fluxes for Aluminium Melting can be divided into refining agent,……

Gas purifier purification refers to the introduction of gas into the aluminum melt or the substances that can produce purified gas. The partial pressure difference……