Foam ceramic filter is a new type of molten metal foundry filter developed to reduce casting defects, used to filter impurities in liquid metal. The……

After refining in the static furnace, wait for 30 minutes, the bubbles generated by the refining in the melt, carry the hydrogen that diffuses into……

When selecting the composition of the aluminum liquid refining agent, in addition to the physical properties of the refining agent (such as melting point, viscosity,……

At present, the filtration technology using ceramic foam filters has been recognized as a successful method to reduce the inclusions in the molten metal during……

The most widely accepted and most commonly used method for removing inclusions such as oxide films from molten aluminum is flux refining. The chemical composition……

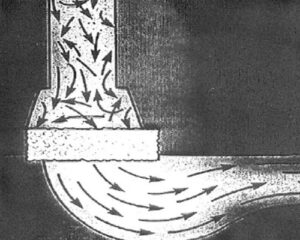

The use of ceramic foam filters to remove inclusions in the foundry industry is well known. The ceramic foam filter works in a deep bed……

Alumina ceramic foam filter for foundry is used to filter impurities in aluminum and aluminum alloy when molten metal enters the mold. Clean liquid metal……

Ceramic foam filtration is widely used to remove non-metallic inclusions in molten metal. Ceramic foam filters (CFF) have been used commercially in the aluminum foundry……

The ceramic foam filter is an extremely effective tool for obtaining the purity of the molten metal during the casting process. The ideal filtration characteristics……

Ceramic filter can effectively filter non-metallic inclusions and impurities in molten metal. Ceramic filters change turbulence and provide laminar and stable melt flow in the……