Melt purification and modification treatment methods can significantly affect the properties of the alloy, especially the toughness and electrical conductivity. Research and develop various advanced……

Rotary degassing with inert gas was first applied to continuous aluminum liquid refining in large melting furnaces. Each rotating nozzle is composed of a graphite……

With the rapid development of automobile lightweight technology, the steering action of aluminum wheels is required to be more precise. In order to prevent the……

AdTech has developed aluminum granular fluxes. Granular Fluxes have the best impurity removal and purification treatment effect, and show the minimum value in the environmental……

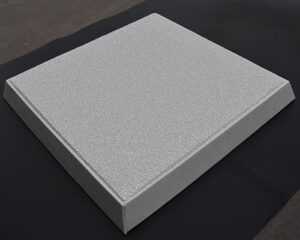

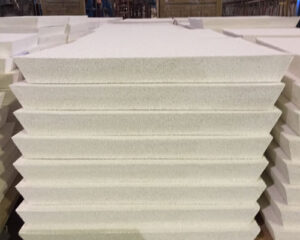

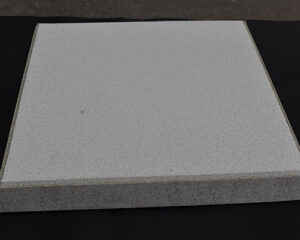

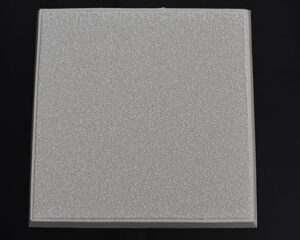

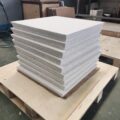

The alumina ceramic foam filter is suitable for the filtration and purification of aluminum and aluminum alloys. It is composed of alumina, silica, talc, and……

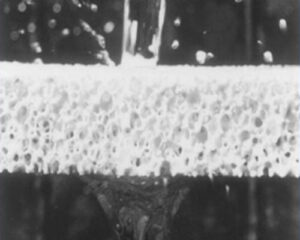

In the production of castings, the use of foam ceramic filter metal liquid filtration technology, through mechanical interception, rectification scum, and deep adsorption three filtration……

The selection of the aluminum melt filter should be based on the quality of the impurities in the aluminum melt, the flow rate of the……

The use of ceramic molten metal filter to remove impurities in the aluminum melt is currently a method widely used by aluminum processing manufacturers. It……

The molten metal filtration process is very important. It is the last step before casting and determines the quality of the casting. In order for……

After placing the AdTech ceramic foam filters in the filter system, the filter produces a comprehensive resistance to the molten metal. This resistance mainly includes:……