The floatation method is currently the most widely used degassing method of molten aluminum. The principle is to pass an inert gas or an active……

As an important branch of the three major categories of foam ceramics (alumina, silicon carbide, and zirconia), alumina ceramic foam is also the earliest used……

A new type of online degassing equipment developed by AdTech – online degassing refining device. The molten aluminum flows through the degassing box, and the……

What is degassing aluminum? Degassing aluminum is mainly to purify hydrogen in molten aluminum. During the smelting process of cast aluminum alloy, there will be……

Aluminum foil has a series of advantages such as light weight, airtightness, good coating, non-toxic and moisture-proof, so it is widely used in the national……

The pouring temperature of the cast-rolling production is the melt temperature in the front box. Because the melt temperature in the front box is easy……

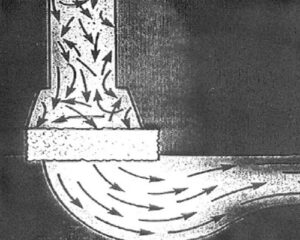

Air slip casting is also called gas-pressurized hot top casting. It is a new casting technology developed on the basis of the hot top, which……

Aluminum alloy purification adopts smelting furnace nitrogen powder injection refining and international advanced degassing filtration system. The online degassing system adopts rotor gas refining technology,……

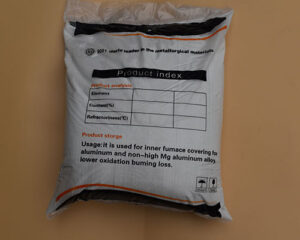

Covering Flux is used to prevent aluminum from being oxidized inside the furnace, thereby reducing oxidation and combustion losses. We have 2 types, sodium type……

Hop top Casting Sprue Bush is widely used in the hot top casting of aluminum and aluminum alloys. It is used in conjunction with the……