The casting defects of the aluminum shell castings of the gasoline engine turbocharger compressors are analyzed. The possible causes of these defects are analyzed. After the quality analysis of the molten metal, the reasons for using ceramic foam filters to improve the casting process are given, which have been verified in actual production. Using the ceramic filter for metal casting, the rejection rate is significantly reduced, effectively reducing the production cost.

The aluminum casing of turbocharger compressor adopts metal gravity casting, and the sand core is a coated sand core. Due to the rapid temperature drop during the filling process of molten aluminum in metal mold casting, rapid filling is required. The pouring temperature is 710°C, the mold preheating temperature is 300-350°C, the filling time is about 6s, and two layers of fiber filter screens are set at the root of the sprue.

In actual production, a large number of defects such as inclusions and entrainment appear in castings. In severe cases, oxidation inclusions block the product section, and the formed penetrating defects cause serious air leakage. Holes will appear after the surface shot blasting treatment, and oxides throughout the entire wall thickness can be seen on the fracture section.

In order to further analyze the types of defects and the reasons for their formation, the defects of the castings were sampled for metallographic observation, and it was found that there were defects such as oxide inclusions, holes and shrinkage. The above-mentioned defects may usually be caused by unqualified aluminum liquid treatment, failure to effectively degas and remove slag, and finally enter the casting; or the improper design of the pouring system may cause turbulence and splashing during the pouring process.

The analysis of molten metal carries out nitrogen refining treatment on the molten aluminum. After the treatment, the molten aluminum is tested by a hydrogen detector. The result shows that the H2 content in every 100gAl is 0.15ml. The metallographic sample also showed clean and no slag. Therefore, it is judged that the gas, slag, and inclusion defects in the casting are not brought into the casting of molten aluminum.

After the numerical simulation analysis eliminated the cause of casting scrap caused by molten aluminum, the original process was numerically simulated using the MAGMA software. The simulation results show that the molten aluminum is directly spread on the upper part of the casting after passing through the filter to fill the upper part of the casting, and then rolls down after partial filling. The speed is fast, turbulence, splashing and entrainment are serious.

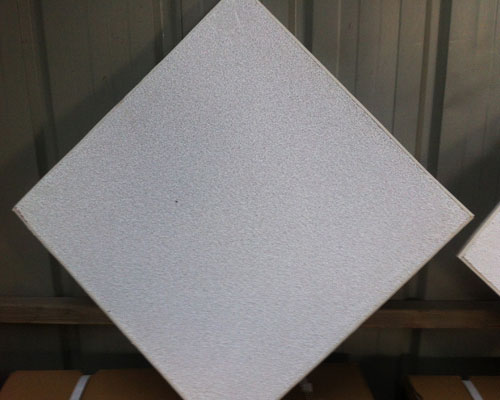

Casting defects are mainly caused by the failure to effectively control the filling process. Therefore, adjusting the pouring system to make the filling stable can effectively avoid defects. The use of ceramic foam filter is one of the simple and effective ways. The foam ceramic filter replaces the fiber filter in the original process. The filling process is stable, avoiding turbulence, entrainment and splashing, and the bottom is filled first, and the feeding is guaranteed.

The ceramic foam filter for metal casting not only has a good filtering effect on molten aluminum, but also effectively avoids the generation of endogenous oxidized inclusions.