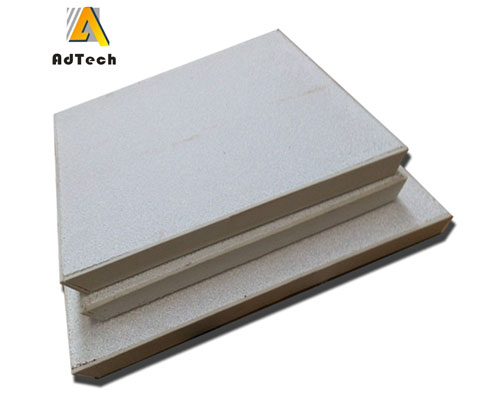

Foam ceramic filter for cast aluminum is made of alumina and is designed to be applied to the purification process in the production of non-ferrous metals such as aluminum and aluminum alloys. It is also used in various sewage treatment, separation media, catalyst carriers, sound absorption and environmental protection.

Foam Ceramic Filter for Cast Aluminum Product Features

- High dimensional accuracy

- High mechanical strength

- Stable chemical composition, resistant to corrosion of liquid aluminum and its alloys

- Purify molten aluminum and improve the quality of aluminum

- Reduce defects and reduce defective rate

- Reduce costs and increase production efficiency

- Simple and flexible to use

- The size is from 20mm to 600mm to meet the needs of different customers

AdTech ceramic foam filters for casting have all common sizes: 7″, 9″, 12″, 15″, 17″, 20″ and 23″.

We offer all porosities from PPI 10 to PPI 60 (PPI = number of pores per inch). You can also customize the size of the projection filter.

The edge of CFF is equipped with gaskets. The gasket ensures the correct and tight position of the filter in the filter housing. For example, there are different types of gaskets. Ceramic fiber gaskets, etc. You can also choose CFF without gaskets.

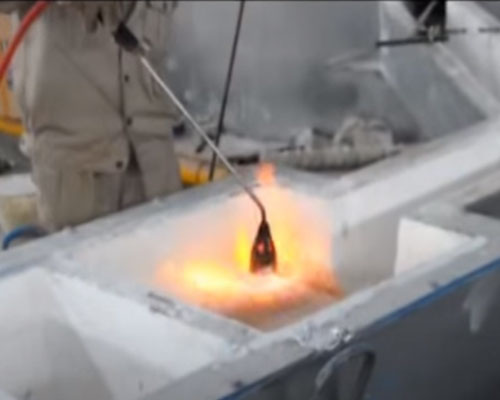

How to Use Ceramic Foam Filter

- Check and clean the debris on the surface of the aluminum fusion filter to keep the aluminum fusion filter clean and complete.

- Gently place the Foundry filter into the filter box, and then manually press the gasket on the filter plate to prevent molten aluminum from flowing or floating.

- Preheat the molten aluminum filter device and the cast filter uniformly to make it close to the temperature of the molten aluminum. The preheating temperature of the cast filter is not lower than 260℃.

- Preheating to remove the adsorbed water helps to temporarily open the pores of the cast filter and prevents heat from rising and shrinking to block certain holes in the cast filter. The preheating can be electric heating or gas heating. Normal heating is 15-30 minutes.