CFF filtration efficiency is only related to the thickness of the filter and the speed at which the melt passes through the filter. The greater the thickness of the filter, the better the filtering effect; the faster the melt passes through the filter, the worse the filtering effect.

In casting and rolling production, the amount of melt filtration per unit time is small, the flow rate is slow. And the aluminum and soft alloys have few inclusions, and the inclusions are easily absorbed by the filter, and the CFF filtration efficiency is high. Relatively speaking, the aluminum melt is relatively easy to purify. Generally, 50PPI and 30PPI two-stage ceramic foam filters are used for filtration.

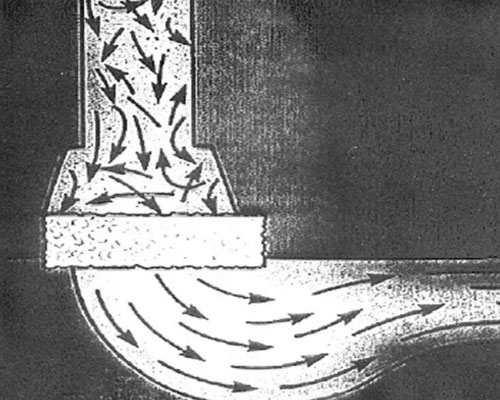

Compared with casting and rolling, the production situation of casting is more complicated. The flow rate is large, and the filter is filtered in the same way as the cast-rolling production. In order to ensure the same filtration efficiency, the flow area of the filter must be increased, so that the flow rate per unit area of the filter is equal to it. Secondly, the hard aluminum alloy melt contains tiny slag particles is much higher than that of pure aluminum and soft alloy.

In order to ensure the quality of the final product, it is best to use the tubular filter, which not only increases the surface area of the filter in contact with the melt, but also reduces the flow rate per unit area of the melt, ensures the filtration efficiency and the total flow rate, and meets the needs of production. The pore size of the filter increases the porosity to improve the filtration accuracy and reduce the residual number of fine particles in the melt.

Tubular filtration can greatly improve the quality of casting products and meet the needs of high-end products. However, this increases the initial pressure of the filter melt, which increases the difficulty of the operation and at the same time increases the filtration cost.

Compared with the corundum tube, the ceramic foam filter has a larger pore diameter, a smaller density, and a lower filtration accuracy. But this can be improved by increasing the number of filtration stages, that is, two-stage and three-stage filtration can be used to improve filtration accuracy. Its advantages are small initial pressure head, convenient replacement, simple operation, and better filtering effect.