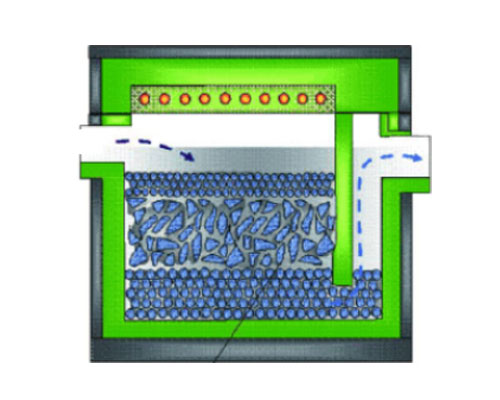

The deep bed filtration device consists of several layers of alumina balls and gravel layers. The particle size selection of the filter material and the distribution of different layers play an important role in optimizing filtration efficiency.

Before the liquid metal is filled, the filter bed must reach a temperature thoroughly to ensure that there will be no solidification in the bed. Dry air or another kind of emotional gas is circulated to the filter to preheat the bed. The gas is fed into the lid, and the air is heated to a high temperature by the resistance wire radiating in the lid. It is then conveyed down to the filter bed and through the pipe to the outlet. The temperature of the preheating operation is monitored by a thermocouple inserted in a special position in the bed.

When the deep bed filtration device reaches a temperature suitable for charging, the initial filling operation is to send the aluminum liquid into the alumina ball layer and alumina grit plane layer of the filter bed through the inlet pipe, and obtain the required layer under the proper aluminum liquid flow rate. The flow is evenly distributed at the bottom of the filter bed, and then slowly passes through the filter bed to the surface.

When the casting starts, it is extremely important to control the temperature of the filter bed during the whole process of maintaining the casting state. Because any cold zone causes the metal to solidify, it will negatively affect the filtration efficiency.

The advantages of the deep bed filtration device are a thick filter layer, long flow path, and many impurity particles adsorbed. Large over-flow, suitable for large-scale and mass production. However, deep bed filtration only uses filling to form a filter layer, and the filter medium is easy to loosen and move, causing some small impurities to be stirred into the melt and reduce the filtering effect.

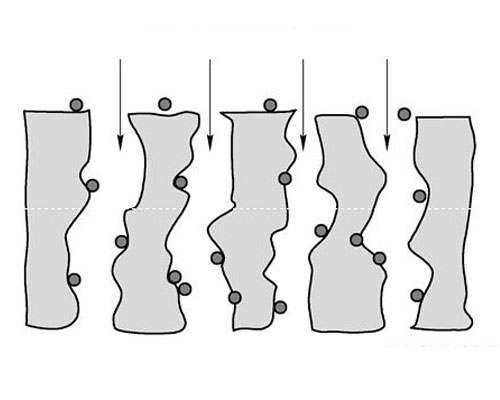

Compared with the deep bed filter, the ceramic foam filter has a thinner filter layer and fewer impurity particles that can be adsorbed. But this can be improved by increasing the number of filtration stages, that is, two-stage and three-stage filtration can be used to improve filtration accuracy. Its advantages are small initial pressure head, convenient replacement, simple operation and better filtering effect.