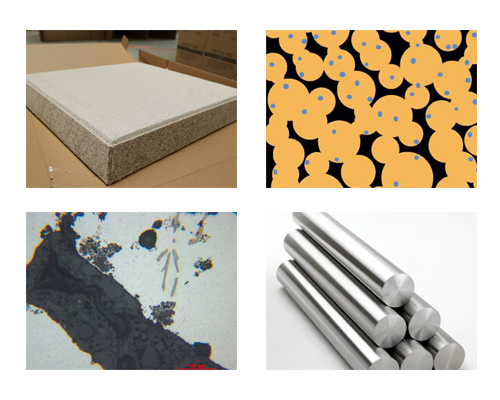

Both DBF and CFF are based on the same deep filtering technology. Deep Bed Filtration (DBF) and Ceramic Foam Filtration (CFF) technologies are representative of the development of on-line filtration technology outside the modern melt furnace. Both deep filtering technologies can achieve better quality requirements when used on corresponding products. CFF has been widely used in actual production. It is a very common online filtration system for the production of standard products. The DBF deep filtration technology is suitable for the mass production of thin products, and it has a more prominent filtration efficiency.

Deep Filtering Principle

The molten metal filter is a multi-empty medium, and the molten aluminum flows in this medium according to the set route. In order to avoid the second pollution caused by the oxide layer, the movement in the gap is a layered trajectory. Particles are blocked by four methods (direct interception, inertial force, Brownian motion, and gravitational precipitation). The impurities are gradually absorbed, gradually blocking the filter layer. The filtration efficiency increases with the increase of the particle size of the inclusions and the thickness of the filter, and decreases with the increase of the pore size and metal flow rate.

No matter what kind of filter, the size of the impurity particles that can filter out is much smaller than the size of the pore size of the filter medium. The reason is that the impurity particles are captured by the filter medium. There are mainly four situations as follows:

(1) Direct interception. When the size of the impurity particles is larger than the pore size of the filter medium, they are blocked out of the pores and filtered out.

(2) The inertial force causes the impurity particles to deviate from the flow direction of the fluid, and are attracted by the thin wall of the pores of the filter medium and are retained.

(3) The impurity particles make irregular Brownian motion in the melt, and when they collide with the filter medium, they are adsorbed by the medium and stayed.

(4) Impurity particles are deposited on the wall of the filter medium due to gravity and captured.

No matter what filtering method is used, the filtering effect is related to the flow rate of the filter element. The lower the filtering speed, the better the filtering effect, and vice versa.