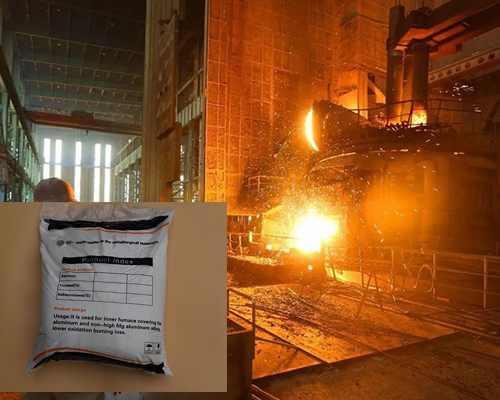

Flux for Aluminium Recycling is mainly used to remove hydrogen and scum from aluminum and aluminum alloy melts, to make the aluminum liquid more pure, and it also has the effect of removing slag.

Refining Agent is easy to decompose at high temperature, and the generated gas can react with hydrogen. The gas and H strongly adsorb the slag and quickly escape from the melt. As the bubbles rise, they are brought to the surface of the molten aluminum to achieve the purpose of refining and purifying, degassing and removing slag.

Flux for Aluminium Recycling can be used in a variety of aluminum alloy melts, and can be used for pure aluminum smelting, refining, and slagging.

Only need to sprinkle the refining agent on the surface during use, dissolve it in the aluminum liquid quickly and stir it fully. If a jet is used, it is best to use an inert gas to inject the refined agent, for example, nitrogen and argon can be selected.

Refining flux for aluminum melting is a white powder or granule with uniform particle size. Its main components are chloride salt and fluoride salt. After proper heat treatment and sieving, it is beneficial for the nitrogen in the refining tank to enter the lower layer of molten aluminum uniformly through physical and chemical changes.

Flux for Aluminium Recycling is economical and can meet the production of high value-added, high-tech performance aviation, transportation and other aluminum alloy precision castings.

Novelis, the world’s largest aluminum recycling company, announced that it will spend US$375 million to build a factory in Zhenjiang, China for the recycling and manufacturing of aluminum products for the automotive industry. Metal recovery is crucial in the energy transition, which will require a shift from internal combustion engines to electric vehicles. According to Novelis, a subsidiary of India’s Hindalco, the expansion project is expected to be completed in mid-2024.

This investment will establish a fully integrated supply chain for the Chinese automotive market between the Zhenjiang Rolling and Recycling Plant and the Changzhou Automotive Painting Plant.

Novelis, the world’s leading automotive sheet manufacturer, said that Novelis processes nearly 2 million tons of aluminum scrap each year and produces an average recycled content of 61%. Recycling aluminum can save 95% of the energy used to make new metals.