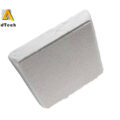

Foam ceramic casting filters have many advantages such as good chemical stability, high specific strength, high temperature resistance, thermal shock resistance, and large specific surface area. They are widely used in metallurgy, chemical industry, environmental protection, and other fields. In metallurgy, the use of ceramic foam filter plates can remove heterogeneous impurities in the aluminum melt, such as slag and inclusions, and is one of the most effective melt purification methods.

Studies have shown that while removing slag, foam ceramic casting filters can also reduce the hydrogen content in the aluminum melt. Because of its good slag removal effect, simple operation, easy matching with other parts, and low cost, it has become a conventional purification method in the aluminum processing industry. With the increasing requirements for the quality of aluminum products, the requirements for the filter plate are also getting higher and higher.

Inclusions are the most common type of casting defects. There are many process steps in casting production to reduce casting inclusions, such as the selection of furnace materials, the removal of metal scum before pouring, and the covering of slag collectors on the ladle. The pouring ladle is made of bottom pouring type or teapot type, the pouring system is made of closed type, and the horizontal runner is equipped with slag collecting bag and slag collecting trough.

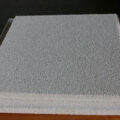

The liquid metal filtration technology was developed in the 1970s and was first applied to aluminum alloys. Because of the low melting point of aluminum alloys, the density of alloys and oxides is almost the same, and the inclusions are difficult to float. The first generation product-woven filter, the second generation product-extruded straight hole filter; the third generation product-foam ceramic filter.

Ceramic Foam Filters, referred to as “CFF” (Ceramic Foam Filters). Generally, polyurethane foam is filled with ceramic slurry, and then the slurry is extruded, leaving the ceramic material wrapped around the foam fiber, which is baked and sintered at high temperature, and the polyurethane is decomposed by heat, leaving a foamy ceramic products-ceramic foam filter.

This kind of ceramic filter can be used in various casting alloys, and the product has been commercialized. This kind of filtration process has been widely promoted in industrially developed countries, and it has become the simplest and most effective method to improve the mechanical properties of castings and reduce pores and inclusions.