Technical transformation to improve the quality of melt purification materials and equipment

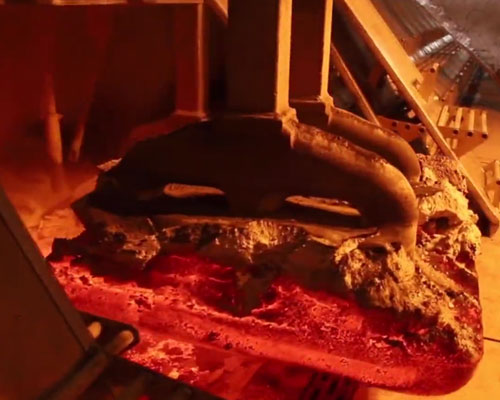

Melt purification improves the refining quality by aluminum alloy furnace, online degassing, filtering and diversion protection of non-wetting materials.

1. Replace the chlorine in the furnace and online refining.

2. Smokeless refining, zero fluorine emission, fully in line with environmental protection.

2. Solve the problem of difficult sealing in the industry. High resilience double sealing material and built-in air lock seal to isolate secondary air pollution.

3. By combining the 0.54w/m.k low-conductivity lining material with the insulating structural material, the average shell temperature can be controlled at 65.

4. The removal rate of alkali metals (sodium, calcium) is 50-80%.

Classification and control of the purity of hydrogen and inclusions in aluminum alloy products

According to user requirements, use online hydrogen and slag measurement methods to divide the measurement data.

For products such as ultra-thin aluminum foil and can body materials with first-class purity, the hydrogen content is determined to be no more than 0.10ml/100gAl, and the slag content is determined to be no more than 2K/kg.

For important use products such as aerospace, high-speed rail, double zero foil, can cover material, CTP board, automobile board, rail transportation and other important products with secondary purity, the hydrogen content is determined to be no more than 0.12ml/100gAl, and the slag content is determined to be no more than 2 -5K/kg.

For ordinary aluminum alloy products such as curtain wall decorative panels with grade 3 purity (except for special requirements), the hydrogen content is determined to be no more than 0.2ml/100gAl, and the slag content is determined to be no more than 5-80K/kg.

Production control of the purity of aluminum alloy melt

First-grade purity products: First-grade scrap can be added, master alloy or aluminum additives-gas refining (Ar2 gas or mixed gas) for remelting flux protection and alloy protection-configuration of rotary degassing/vacuum degassing-adoption foam ceramic filter tube type.

Secondary purity products: secondary waste can be added and metal additives can be used-gas refining (N2 gas) for flux protection and alloying protection-configurable rotary degassing/vacuum degassing-can use two-stage ceramic foam filter /foam ceramic filter tube or deep bed for filtration.

Three-level purity products: third-level scrap, scrap aluminum and metal additives-gas refining (N2 gas) protective flux-foam ceramic filter can be added.