The ceramic movable molten metal trough is mainly used for the transportation of molten aluminum and aluminum alloy. The product has the characteristics of good thermal insulation performance, non-stick aluminum, and erosion resistance. The surface of the runner products is dense and dense, smooth like enamel, high strength, and light weight.

The molten metal launder made of traditional castables has a large temperature drop during the long-distance transportation of molten aluminum. We recommend using refractory fiber launder instead, and can be used with refractory fiberboard as the cover plate, which can greatly reduce the heat loss.

If the traditional casting material launder is damaged, it can only be removed and re-poured; while the ceramic fiber movable launder can be repaired with fibers, and timely repair and maintenance can extend the service life of the launder.

The high temperature resistant movable molten metal trough has an excellent resistant launder lining for the conveying of aluminum and aluminum alloy melt. It directly contacts the melt, has excellent heat preservation performance, thermal shock resistance, compressive strength. The aluminum melt is scoured for a long time, does not collapse, and is not easy to peel off, which minimizes the secondary pollution problem of the aluminum melt in the conveying link.

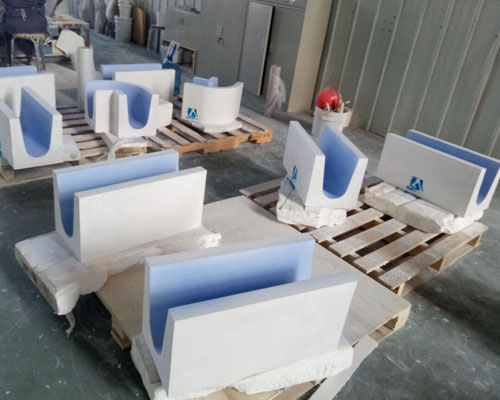

The ceramic fiber launder and trough have a long service life. Special raw materials are completely non-wetting with aluminum, and the launder liner is painted with BN coatings, which can extend the launder service life.

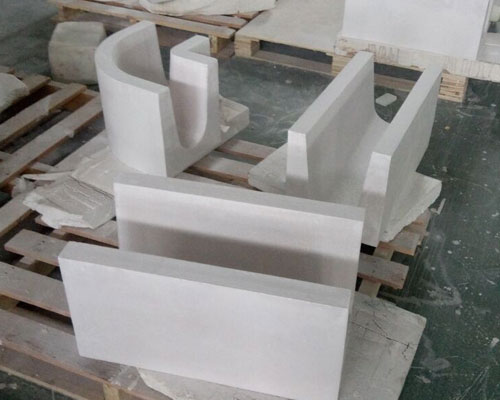

Ceramic Fiber Molten Metal Trough Features

- Color: off-white

- Raw material composition: ceramic fiber and inorganic ceramic material

- Dimensions: according to customer requirements, according to drawings

- Standard size tolerance: length ±2mm width ±1mm

- Other properties: according to customer requirements, the density can be light or heavy

- Thermal conductivity: <0.12W/m.k at 720℃

- Maximum operating temperature: 1250℃

- Continuous use temperature: 800℃

In addition to the launders and trough, our company also produces ceramic foam filters, degassing and filtering units, fluxes, casting tip and nozzle, vacuum shaped products used in the aluminum casting process. Products of various specifications can be designed and produced according to user requirements.