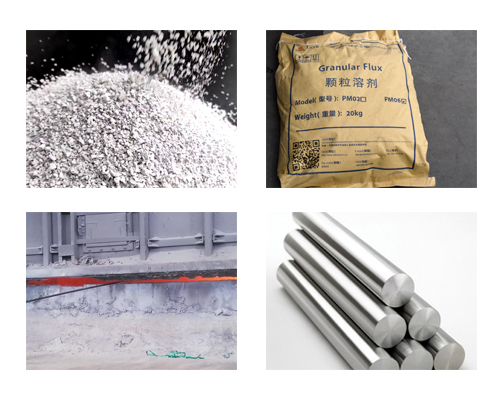

Flux is a kind of high-efficiency purifying flux for electrician aluminum round rods. When equipped with melt filtration, the purification effect will be significantly improved, and the impurity removal rate and porosity reduction rate can reach 83.6% and 91.2% respectively, and can improve the existence of gas and impurities, thereby showing the mechanical properties of the material, especially the plasticity.

Due to the development of science and technology, the field of aluminum melt purification is progressing rapidly, and the purification of the melt is an important method for the purification of aluminum melt.

Now, in addition to the flux that can be removed and used as the main purpose of removing impurities, there are some other fluxes, such as covering agents, slag cleaning agents, etc. According to the purpose of purification and the purifying flux of aluminum melt, there are three categories: gas purifying agent, impurity removal flux and purification flux.

Gas purifier purification refers to the introduction of gas into the aluminum melt or the addition of substances that can produce purified gas, and the partial pressure difference between hydrogen in the aluminum melt and the bubbles is used to diffuse into the bubbles, and the bubbles are captured during the process of floating. Inclusion of scum, etc., so as to achieve the purpose of removing hydrogen and impurities. The main purpose of gas purifiers is to remove hydrogen. At the same time, because the impurities in the melt interact with hydrogen, the process of removing hydrogen is accompanied by impurity removal.

The impurity removal flux is mainly for impurity removal. The essence of impurity removal is to use the difference in physical or chemical properties between the inclusion and the aluminum melt to achieve the separation of the two to achieve the purpose of impurity removal and hydrogen removal.

In addition to the main purpose of degassing and impurity removal, there are many kinds of purification fluxes with different functions. The purification essence is the difference in wettability between the inclusion and the melt when the liquid flux is used to purify the melt, so that the inclusions spontaneously The ground moves from the melt into the flux, and at the same time, the gas diffusion and dissolution adsorption are used to achieve the purpose of impurity removal and hydrogen removal.