Refining Flux for Aluminum is a key product for improving the purity of molten aluminum. How to use new fluxes to reduce costs and improve quality for aluminum companies has become our key research project.

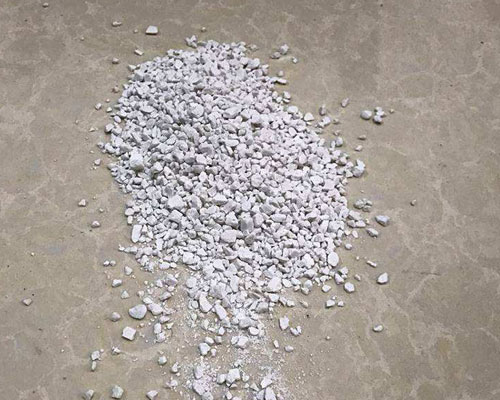

The high-efficiency sodium-free granular refining flux for aluminum produced by AdTech has the functions of covering, removing slag, degassing, deterioration and refinement, and can purify molten aluminum. Compared with ordinary refining agent, the amount of granular refining agent is reduced by 40-60%. Because the aluminum content in the aluminum ash is reduced due to the thorough slag removal, the purity of the aluminum liquid is improved, and the ash output of the aluminum ash is reduced by 25-35% and greatly increased The recovery rate of secondary aluminum, the reduction of energy consumption and the cost of subsequent aluminum ash treatment.

In addition, there is no smoke in use to reduce environmental impact and improve the work intensity of workers. The molten aluminum impurity only needs to be added once, the operation is simple, there is no violent reaction during the reaction process of the molten aluminum, no smoke, no irritating odor, compared with other molten aluminum solvents, the effect of slag removal and degassing is good, which reduces the labor of workers Strength, improve the working environment, improve work efficiency, because this product does not contain sodium ions, it is also suitable for casting aluminum alloy.

Because this sodium-free granular refining flux product has the effect of deterioration and refinement, it can improve the organization, physical and mechanical properties of aluminum products after application, enhance product tensile strength, stabilize elongation, improve surface brightness and product qualification rate. The scope of application is suitable for the smelting of deep-processed raw materials such as casting aluminum alloys, plates, rods, tubes, die castings, aluminum plates, strips, and foils. The actual amount of the user can appropriately increase or decrease the melting amount according to the impurities in the aluminum water. When the temperature of the molten aluminum is more than 680°C, a nitrogen blowing device is used to blow the powder flux into the depth of the molten aluminum to cause a reaction, so that the bubbles will absorb hydrogen atoms during the floating process to achieve degassing, slag removal, and grain refinement. purpose. Packaging and storage: 2.5kg or 5kg/bag, 20kg/carton. Ventilated and dry, the bag must be used immediately after opening, and it must be sealed if it is not used up.