Aluminium foundry ceramic filter is also called alumina ceramic foam filter. It can effectively remove large inclusions in molten aluminum and absorb micron-sized particles of inclusions, which can improve surface quality, improve product performance, improve microstructure, and increase yield. It is widely used in the production fields of aluminum profile, aluminum foil, aluminum alloy, and so on.

Alumina foam ceramic filter is used in the aluminium foundry to remove non-metallic inclusions and molten metal in the oxide film. Foam Ceramic Filter is used in the production of aluminum alloy, aluminum plate, aluminum profile and other production departments. It can effectively remove large inclusions in molten aluminum, adsorb small particles of fine inclusions, purify the hydrogen content in molten aluminum, and reduce hydrogen atom adsorption and oxidation.

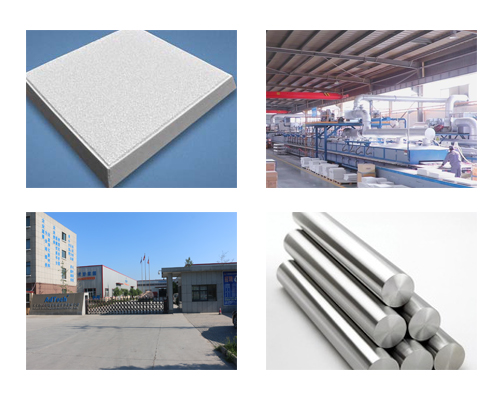

Ceramic filter for aluminium foundry is a very economical and effective filter that can filter out non-metallic solid inclusions in aluminum and aluminum alloy melts. The ceramic foam filter plate is made of foam sponge and high-purity ceramic materials with a good open-cell structure, and is manufactured under strict quality control. It has high through-porosity, sufficient sintering, and good flexural and compressive strength to ensure a high-efficiency filtering effect.

We mainly provide ceramic foam filter plates with various pore sizes ranging from 20 to 60 PPI, with a complete range of sizes. Foam ceramic filter plates are widely used in the filtration and purification of various aluminum and aluminum alloy melts in continuous casting, semi-continuous casting, gravity casting, and low-pressure casting. In addition to general specifications, it can be designed and manufactured according to customer needs.

Before use, it is important to preheat the filter and filter box. During the preheating process, care must be taken to control the heating speed and temperature distribution. This can minimize the thermal shock and strain on the filter and the filter material of the filter box.