As the first process of aluminum processing, if the billet has “innate defects” (such as inclusions, pores, etc.) caused by the casting, no matter what……

Compared with other purification methods in the purification furnace, the aluminum casting flux refining method and gas refining method have a series of advantages such……

Generally speaking, furnace purification includes flux method, gas refining method (active and degradable gas), vacuum purification, and field purification. Among them, flux purification and gas……

As we all know, aluminum melt purification is generally divided into furnace purification and online purification according to the time sequence of its purification treatment.……

At the melting temperature, the aluminum slag remover flux is in full contact with the molten slag on the surface of the molten aluminum, so……

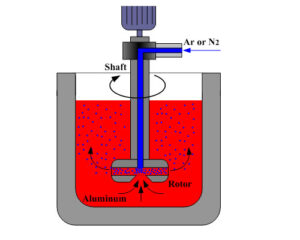

Aluminum alloy liquid degassing of hydrogen can use the adsorption effect of refining agent to achieve the effect of removing oxidized impurities and gas. Inert……

Ceramic Foam Filter Function Impurity and slag removal: Purify the molten metal while degassing (adjust turbulence). The scrap rate of parts is reduced. Improved parts……

Foam ceramic filters for aluminum generally use polyurethane foam as a carrier, filled with a ceramic slurry made of refractory aggregate sintering aids, binders and……

Ceramic foam is a new type of ceramic filter material developed in recent years. Generally, a filter plate with a thickness of 50mm and a……

The current general molten aluminum purification method is: after the smelting furnace, connect the degassing box and the filter box through the launder, and then……