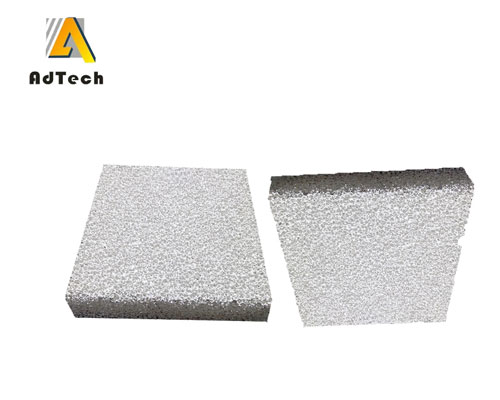

Examples of the ceramic foam filter application effect for molten aluminum

Aluminum Profile Production

Alcoa’s factory used to use 100% waste to produce 6063 alloy as a control experiment. It was first carried out according to a conventional melting and casting process, but half of the gold scraps were filtered with foam ceramic filter plates, and the other half was not filtered. As a result, it was found that a large amount of non-metallic inclusions in the aluminum ingot filtered by the ceramic foam filter plate were removed. In the extrusion test, it was concluded that under the same surface quality, the extrusion speed of the filtered wool extruded was increased by 20%, the extrusion force was reduced by 3%, and the total comprehensive production should be increased by 15%. In addition, the test also shows that the average surface roughness of the profile treated by the foam ceramic filter plate is reduced by about 10% even when extruded at a higher temperature.

Of course, due to the improvement of metal cleanliness, there is no doubt that the service life of the mold will be increased accordingly.

Wire Production

5056 and 5356 aluminum wires are usually used as welding wires. In addition to requiring higher surface quality, metal cleanliness is also very important. The ф0.88 mm 5056 alloy wire produced by Alcoa’s Columbia plant has been used in a comparative test between foam ceramic filter plate filtration and unfiltered. The use of foam ceramic filter plate filtration can reduce the waste rate and increase productivity, and the effect is obvious.

In summary, the ceramic foam filter application can effectively remove various inclusions in the molten aluminum, greatly improve the cleanliness of the metal, and thus help improve product quality and reduce costs. Productivity has been improved to varying degrees, and the operation is easy, the process is easy to control, and there is no need for excessive investment, which is worthy of popularization and application.

The process and device for purifying molten aluminum with ceramic foam filter plates are applicable to all aluminum production departments, including thin plates, strips, foils, bars, pipes, wires, extrusions, forgings, original aluminum ingots, recycled ingots and even The production of cast-rolled billets, etc.