Porous ceramic materials play an important role in cushioning, vibration damping, heat insulation, noise reduction, filtration, etc. High-porosity solids have high rigidity and low density. So natural porous solids are often used as structures, such as bones. While the use of foam ceramic material by humans has not only structural aspects but also many functional uses. Ceramic foam filter is made of foam ceramic material.

The porous material must have the following two elements: one is that the material contains a large number of pores; the other is that the pores are used to meet certain or certain design requirements, so as to achieve the desired performance index.

The relative pore content (porosity) of porous materials varies. According to the size of the porosity, it can be divided into low and medium porosity materials and high porosity materials. The pores of the former are mostly closed, and the behavior of the pores is similar to the inclusion phase in the material. The latter takes three forms with pore morphology and continuous solid phase morphology. The first form is a continuous solid with a two-dimensional arrangement of polygons, and the pores are correspondingly separated by columns, similar to the hexagonal nest of bees, so this two-dimensional porous material can be visually called “honeycomb material”. The second form is that the continuous solid has a three-dimensional network structure, and the formed pores are interconnected. This three-dimensional porous material is called “open-cell foam material“. The third form is a continuous solid with a polyhedral wall structure, which separates closed pores. This three-dimensional porous material is called “closed-cell foam”. Of course, there are “semi-open-cell foams” between open-cell foams and closed-cell foams.

Porous Ceramic Material

The development of this type of material began in the 1970s and is a porous material with high-temperature characteristics. The pore size ranges from nanometer to millimeter, the porosity range is about 20% ~ 95%, the use temperature can be from normal temperature to 1600 ℃.

In general, porous ceramic materials can be divided into two categories: honeycomb ceramic materials and foam ceramic material. The holes in the honeycomb ceramic materials form a two-dimensional arrangement. While the foam ceramic materials consist of a three-dimensional arrangement of hollow polyhedra.

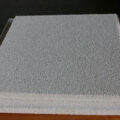

Foam ceramic materials can usually be further subdivided into two types, namely, mesh ceramic materials and closed-cell ceramic materials, depending on whether each cavity has a solid wall surface. For open-cell ceramic materials, the pores are interconnected. If there is a solid wall surface, the foam is called closed-cell ceramic material, where the pores are separated from each other by a continuous ceramic matrix. These differences can be clearly seen by comparing the permeability of the two foams. Some foam ceramics have both partially open pores and partially closed pores.

The open-cell ceramic materials can also have relatively high strength, higher permeability, chemical resistance, high-temperature resistance, and uniform structure.

Pingback:Porous Ceramic Filter,Porous Ceramic Filtration Principle

Pingback:Foam Ceramic Material – 站点标题

Pingback:Foam Ceramic Filtration Mechanism – 站点标题

Pingback:Asian Foundry Filter – 站点标题